Engineering News

Chen's work on nanomaterials in medicine featured in Science Coalition "Research Innovators" spotlight

Research by Pengyu Chen focused on nanomaterials in medicine is featured in the latest "Research Innovators" spotlight by The Science Coalition. Learn more here.

.jpg)

Pengyu Chen

Categories: Engineering, Health Sciences

Auburn ranks among Top 80 for patents in latest National Academy of Inventors recognition

Auburn University has been ranked among the Top 100 U.S. Universities Granted Utility Patents in 2024, a list published recently by the National Academy of Inventors (NAI).

With 20 new patents issued in 2024, Auburn was ranked 80th on the list, seven places higher than the previous year. The list was created to highlight and celebrate American innovation and to recognize those universities that play a large role in advancing the innovation ecosystem within the U.S. and beyond.

Notable among Auburn’s 2024 patents are:

- A patent for improving physical components of mechanical systems using data element mapping and analysis — a methodology currently being tested by industry partners; and

- A patent for an additive nanomanufacturing system and method to facilitate the manufacture of 3D-printed materials in space. The technology will soon be tested in a microgravity environment as part of NASA’s Flight Opportunity program.

“We're thrilled that Auburn continues to be featured on this list. It's a testament to the focus on and strength of innovation on our campus,” said Patrick Reed, executive director of Auburn’s Intellectual Property Exchange (IPX). “An issued patent represents potential commercialization opportunity; collaborating with commercialization partners unlocks that potential, turning it into real-world impact. We look forward to putting these patents to work for the benefit of the public."

In addition to the list, Auburn has been recognized by NAI as several faculty members were named NAI fellows and one named an NAI senior member. The prestigious NAI fellows program honors academic inventors “who have demonstrated a spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on quality of life, economic development and the welfare of society.”

Current and emeritus faculty members who have previously been recognized as fellows include Mehmet Arik, Yonhua Tzeng, J. David Irwin, Joseph W. Kloepper, John Weete, the late S.D. “Dave” Worley, Bruce Tatarchuk and the late Vitaly Vodyanoy. Jin Wang was the first Auburn faculty member to be named an NAI senior member.

Founded in 2010 to recognize and encourage inventors with patents issued from the United States Patent and Trademark Office, the NAI is a member organization of U.S. and international universities and governmental and non-profit research institutes, with over 4,600 individual inventor members and fellows encompassing more than 260 institutions worldwide.

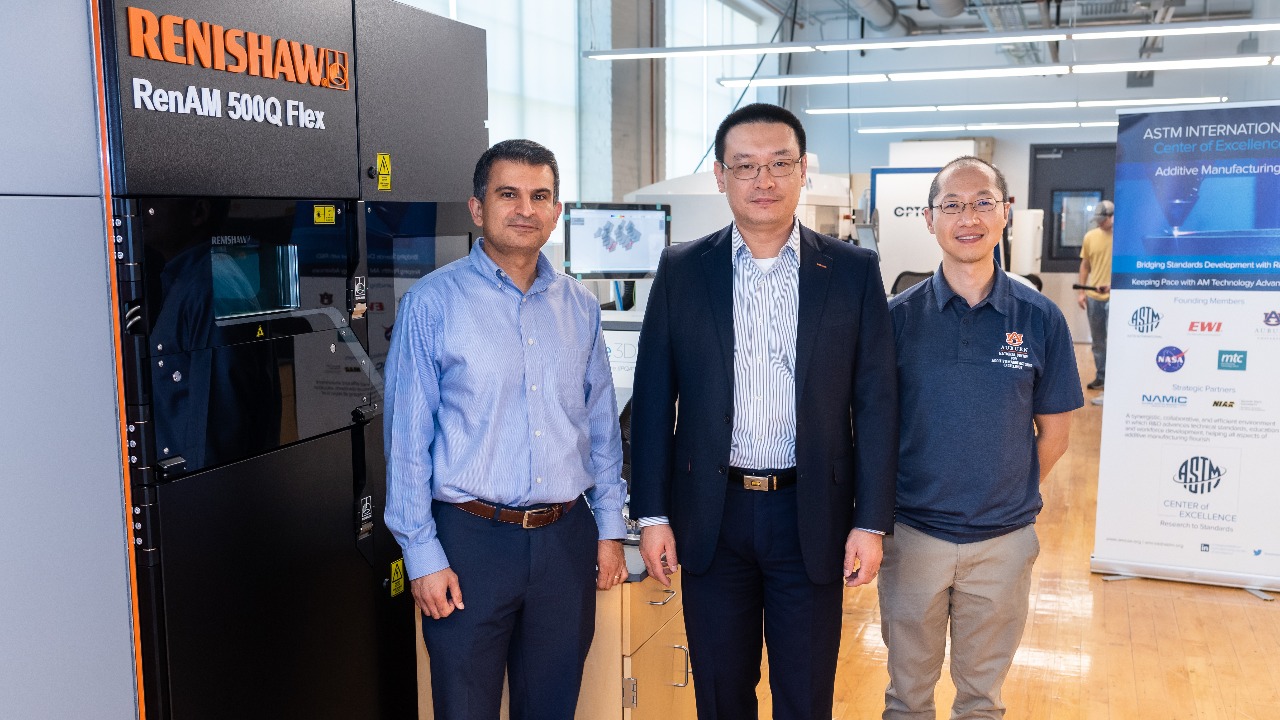

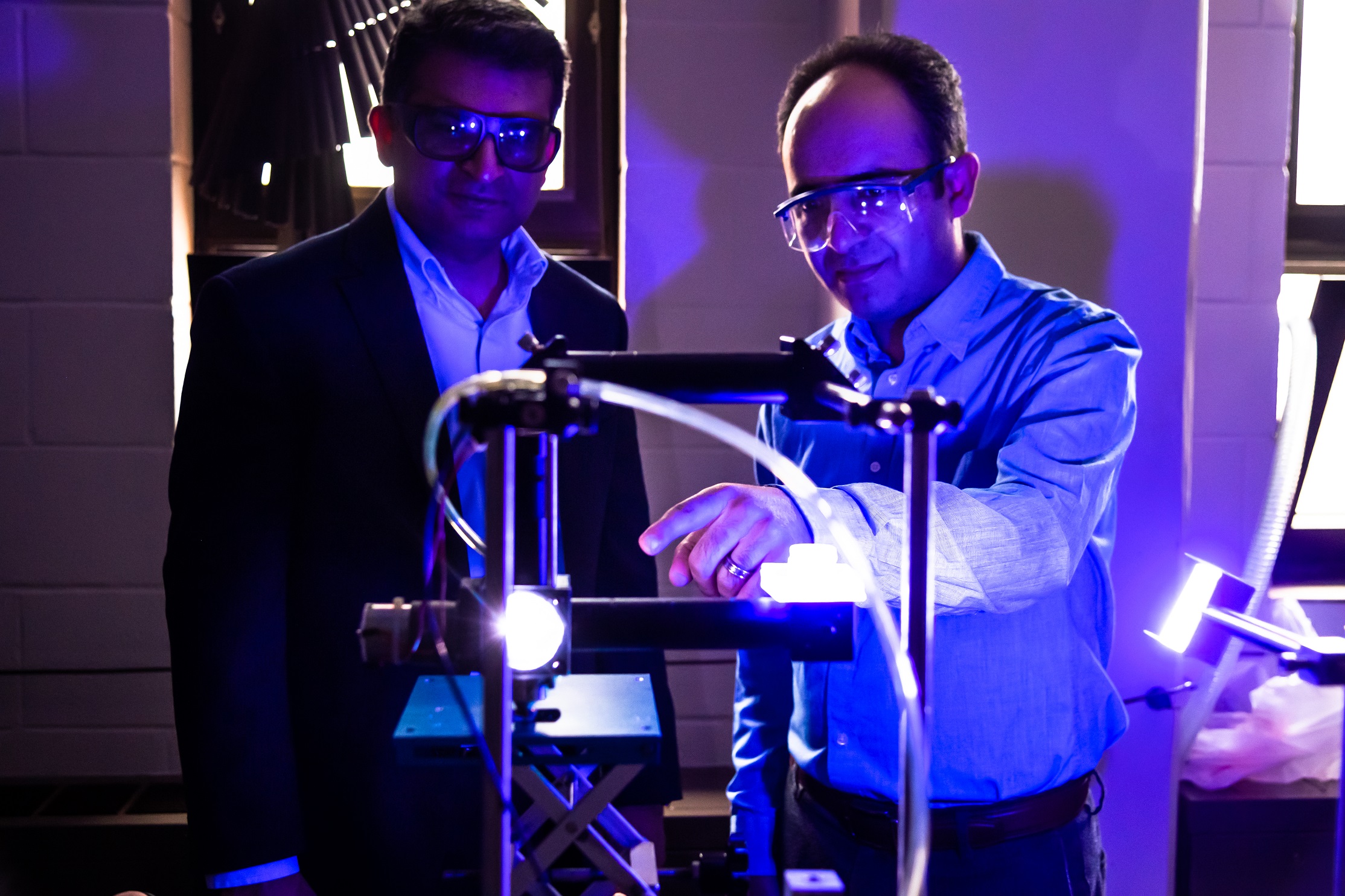

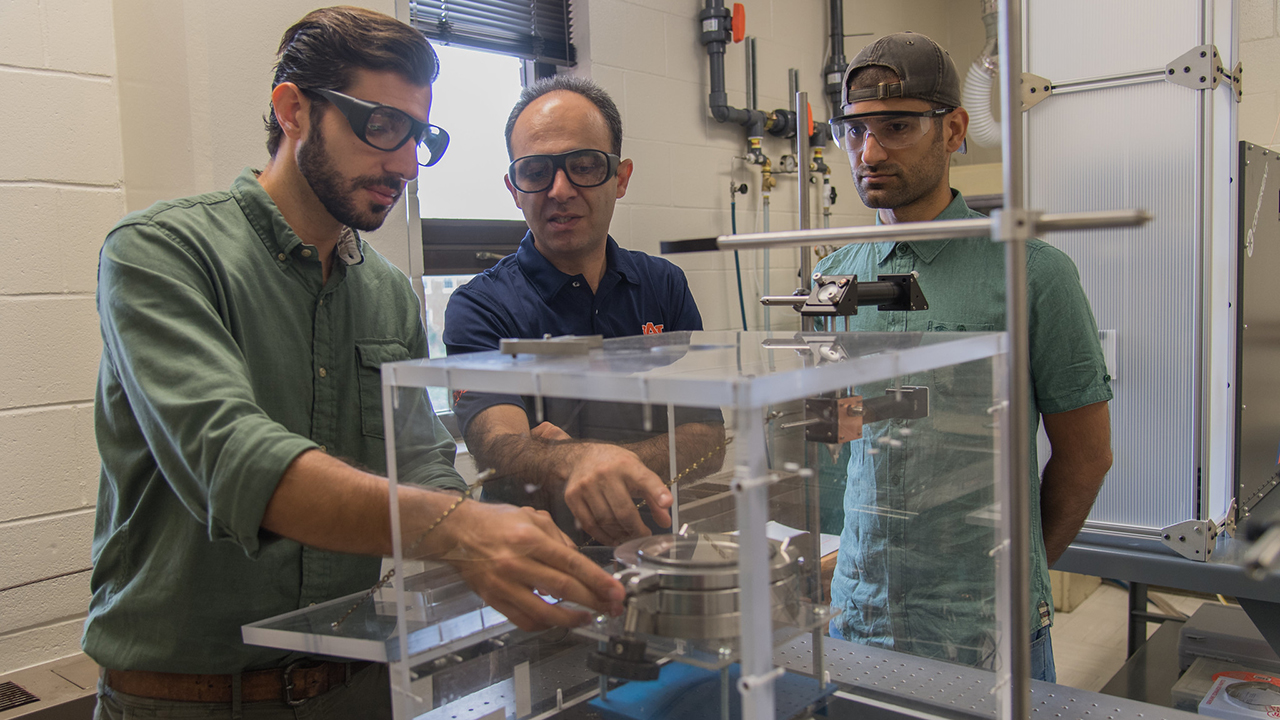

Nema Shamsaei and Masoud Mahjouri-Samani are patent-holders whose innovations contributed to Auburn University's strong showing on a recent National Academy of Inventors list ranking universities granted utility patents in 2024,

Categories: Engineering, Manufacturing, Advanced Systems

New Auburn Engineering research center combines expertise in artificial intelligence, cybersecurity

Auburn Engineering’s newest research center is strategically positioned at the intersection of artificial intelligence (AI) and cybersecurity.

The Auburn University Center for Artificial Intelligence and Cybersecurity Engineering (AU-CAICE), housed within the Department of Computer Science and Software Engineering (CSSE), is dedicated to uncovering pioneering advancements in AI-driven cybersecurity solutions and tackling the most pressing challenges in the digital age.

“In today's rapidly evolving digital landscape, the need for groundbreaking research in artificial intelligence and cybersecurity has never been more critical,” said Allan David, associate dean for research. “The Samuel Ginn College of Engineering is thrilled to continue its role as a leader in emerging technologies, driving innovation and fostering collaboration to address the complex challenges of our time. This new research center embodies our commitment to shaping a safer, more secure future through cutting-edge advancement.”

Gerry Dozier, the center’s first director and the Charles D. McCrary Eminent Chair Professor in CSSE, said researchers will not just focus on AI and cybersecurity, but also three hybrids of AI and Cybersecurity: SecureAI, CyberAI and SecureCyberAI.

“This is based off the two strengths of our department – cybersecurity and artificial intelligence,” said Dozier, who also serves as the Auburn University AI@AU technical lead. “For years, we’ve been working in AI for security (CyberAI), as well as in security for AI (SecureAI).

“SecureAI applies security measures to protect an AI system from adversarial attacks. CyberAI applies AI to the area of cybersecurity, and SecureCyberAI will be best served by security measures that are real-time, self-healing, anti-fragile arms race systems for securing an AI system.”

The AU-CAICE will build upon the foundation laid by the former Auburn Cyber Research Center (ACRC) and advance the legacy of ACRC's pioneering work.

“The center continues to honor ACRC's commitment to cybersecurity excellence while expanding its reach and impact, ensuring that Auburn remains at the forefront of cybersecurity research and education,” David said. “The dedication and achievements of ACRC have paved the way for AU-CAICE to thrive and lead in this critical field.”

“Over the past four years, ACRC has increasingly been focusing on the intersection of AI and cybersecurity, and renaming it as AU-CAICE with all of AI and cybersecurity as its scope, is the logical next step,” said CSSE associate professor Daniel Tauritz, who served in the role of ACRC interim director from June 2020 through December 2024, and will continue in his duties as Auburn University’s Director for National Laboratory Relationships. “Given the critical importance of AI and cybersecurity to national security, the new center is perfectly positioned to meet the nation’s needs in these areas, and I look forward to working with director Dozier to address the Department of Energy’s national security mission.”

Dozier said 27 faculty members, representing engineering, business and other disciplines, are already part of the center.

“We want our new center to be nationally recognized for being a team that successfully develops and cultivates scholarly, long-term, extramurally funded research and educational relationships,” he said. “We also want to serve as a hub of an ecosystem that actively collaborates with academia, business and industry, national laboratories and the government. First and foremost, we want people to see our new center as a tool that can be used to improve their lives and provide them with a competitive advantage.”

Located inside the Shelby Center for Engineering Technology and based in the Gen. Ron Burgess Cyber Laboratory, the AU-CAICE is positioned to work closely with student organizations — including the Auburn University Ethical Hacking Club and Society for Responsible Artificial Intelligence — and peer institutes such as the McCrary Institute for Cyber and Critical Infrastructure Security and the Auburn University Applied Research Institute.

“I am immensely proud of our ongoing efforts to advance research in artificial intelligence and cybersecurity,” said CSSE Chair and AI@AU administrative lead Hari Narayanan, whose department unveiled AI degree and certificate programs for graduates and undergraduates in the past year, mirroring existing degree and certificate programs in cybersecurity, and holds triple designations by the National Security Agency (NSA) as a Center of Academic Excellence in Cybersecurity Defense, Cyber Research, and Cyber Operations.

“The continued emphasis on research and education on these two topics by the department reflects a commitment to excellence and innovation in areas critical to the nation’s future. Our faculty and students play a vital role in driving technological progress in these emerging technologies, fostering a more productive and secure world for all.”

Media Contact: Joe McAdory, jem0040@auburn.edu, 334.844.3447

Categories: Engineering, Cyber, Security

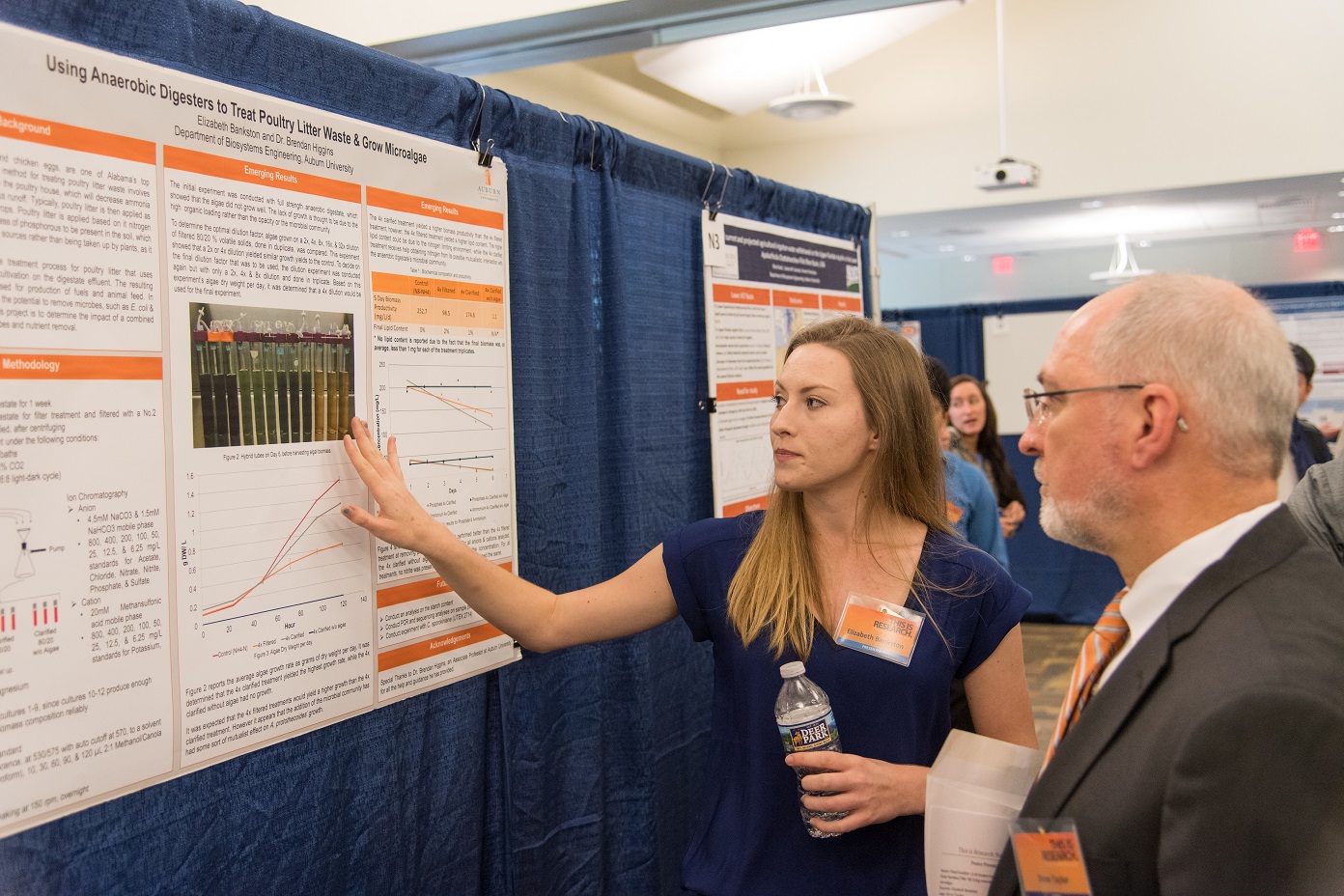

Fueling a winner: Biosystems engineering researcher developing solutions with bioenergy recognized by SEC

Sushil Adhikari had no intention of having a career in academia, let alone researching solutions to some of life’s challenges.

“I just wanted to be an engineer and not study anymore,” he professed.

But plans change.

Nearly 25 years after earning a bachelor’s degree in mechanical engineering from Tribhuvan University in his native Nepal, Adhikari is an Alumni Professor and researcher in the Department of Biosystems Engineering at Auburn University.

He’s also director of the Center for Bioenergy and Bioproducts and, since Feb. 17, the interim associate dean for research for Auburn’s College of Agriculture and interim associate director of the Alabama Agricultural Experiment Station (AAES).

The Southeastern Conference (SEC), on Feb. 24, named Adhikari as Auburn’s honoree for the SEC Faculty Achievement Award.

The SEC annually recognizes one faculty member from each of its member institutions who has demonstrated excellence in teaching, research and scholarship. Recipients are chosen based on their contributions to their field, commitment to students and overall impact on their university.

The conference will proclaim one of the 14 awardees as the SEC Professor of the Year, the highest faculty honor given by the conference, in March.

In good company

Adhikari is understandably proud of the recognition, particularly because this puts him in a class of distinguished colleagues from across campus.

“I never thought that I was going to win this one because of the people who have won this award before,” he admitted.

Auburn's first winner in 2012 was President Christopher B. Roberts, then a professor and chair of the Department of Chemical Engineering, about to be dean of the Samuel Ginn College of Engineering.

Biosystems engineering is housed in agriculture but is a part of engineering. The faculty often intersects. When Adhikari came to Auburn in 2008, his department head was Professor Steve Taylor, who started agriculture’s Center for Bioenergy and Bioproducts.

Taylor would move on to serve as engineering’s associate dean for research and eventually step in as interim dean when Roberts became the university president. Taylor then became the senior vice president for research and economic development, overseeing research endeavors across campus.

Adhikari talks about these colleagues — working with them and filling Taylor’s shoes as center director — as if they are formidable and larger than life. But they share a common thread: impact.

Every role has been an opportunity for each of them to broaden their impact on the lives of students and faculty at Auburn and, with innovative research, the world.

Adhikari stepped into this latest interim gig — Professor Art Appel stepped away from it to be interim dean and interim director of AAES — is simply another chance for Adhikari to make an impact.

Making a difference

It’s something he has been doing since first coming to Auburn.

“Being on faculty gives you the flexibility to focus on your interests. I get to do research and work with students, who grow so much by the time they graduate,” Adhikari said. “For me, it’s about seeing the impact I can have on them.”

The award and his new responsibilities “give me motivation to do more,” he added.

When he isn’t teaching classes, Adhikari is running the Center for Bioenergy and Bioproducts where he mentors student researchers and conducts his own work. He will teach one less class next semester to accommodate his interim responsibilities.

Adhikari doesn’t look at his new role as a burden. It’s a chance “to make a bigger impact.”

“I have worked with a number of faculty, a lot of younger faculty members and students in my role as center director, and I see that I have made some impact, but now the challenge to myself is, can I make a bigger impact at the college level?” he asked.

“It can be difficult to make big changes as an interim, but sometimes it is easier to make changes when you just plant the seed.”

Leave it to a faculty member in agriculture to make such a reference, but Adhikari did it because it’s easy to understand how an idea can grow and flourish, like a seed, with the right tools and support.

He considers students to be like young saplings, who grow into mighty trees with nourishment from Adhikari. This type of influence — as a teacher, researcher, director and interim any job — is what has kept Adhikari on the Plains all this time.

“Maybe I’m just in the right place at the right time, or maybe it’s just my attitude, but I feel fortunate to be here,” he said. “I have the support of colleagues in the department and around campus. I don't see a need to go anywhere else.”

Adhikari has no desire to frame his degrees and hang them on his office walls. Instead, the stark white walls are covered with plaques and certificates he earned over the years. Many denote his collaborative work.

In 2012, for instance, Adhikari, along with Taylor, Roberts, Fasina and others received the President’s Outstanding Collaborative Units Award during the annual Faculty Awards.

The nature of biosystems engineering, what Adhikari calls a problem-focused discipline, lends itself to multidisciplinary cooperation. But what is biosystems engineering?

Addressing challenges

It can be confusing for two colleges to share biosystems engineering, but Adhikari said it makes sense as “we are engineers, trying to solve the problems related to agriculture.”

A sign hangs from the front of the Corley Building, proclaiming the department is developing solutions to life’s essential challenges: “Food, Water, Energy, Environment and Health.”

If that doesn’t clarify the type of work being done inside, Adhikari says, “we try to say that we solve these big problems related to water, food and fuel.”

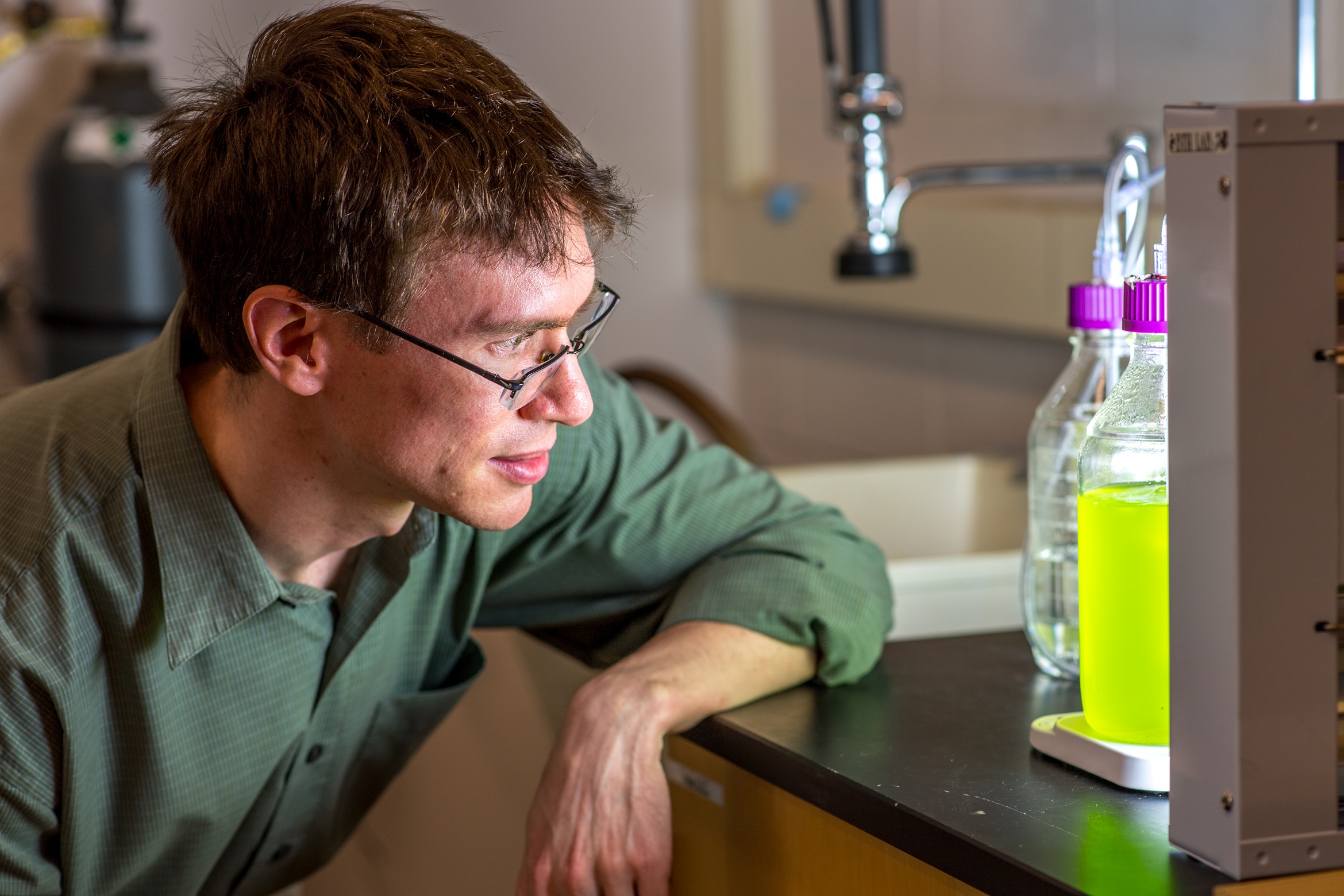

While his office neighbor, Associate Professor David Blersch, is looking at algae growth in high-nutrient wastewater, Adhikari is focused on bioenergy, deriving energy like electricity and biofuel from organic materials (biomass), such as plants and wood.

Adhikari, in collaboration with agriculture faculty, is currently using biochar for agriculture uses for improving soil and water health, reducing greenhouse gas emissions and even killing cockroaches. Biochar — the result of heating biomass like wood, crop residue and manure — is black (like charcoal), extremely light (like Styrofoam) and resembles finely shredded mulch.

Even in their interim roles, Adhikari and Appel can discuss their common work, as Appel is evaluating the efficacy of biochar for killing cockroaches.

With such work happening in the center, researchers like Adhikari and his graduate students seek campus experts in water, soil and horticulture, to name a few, for assistance.

“You need a multidisciplinary approach to solving these problems because these problems are complex,” said Adhikari.

When it comes to biochar, Adhikari believes researchers, like himself, are finding answers to multiple issues. For instance, biochar holds carbon in the soil for hundreds to thousands of years, preventing its release into the atmosphere.

“At the same time, you can improve soil properties with it,” he said. “Capture some of the nutrients from runoff, and you’re looking at other benefits to the ecosystem.”

It boils down to engineering the biochar properties differently to serve unique needs.

Biochar designed by Adhikari's team to help farmers minimize the effects of drought will be engineered differently than the team creating biochar to capture excess phosphorus in the soil and slowly release it to benefit plant growth.

Talk about impact.

Past Auburn SEC Faculty Achievement Award winners

2024, Skip Bartol, College of Veterinary Medicine

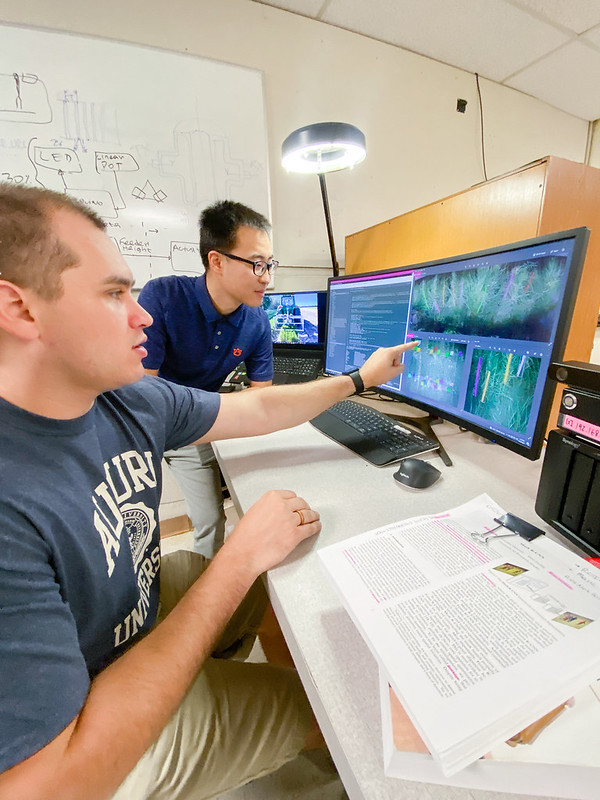

2023, Shiwen Mao, Samuel Ginn College of Engineering

2022, Karen McNeal, College of Sciences and Mathematics

2021, Mona El-Sheikh, College of Human Sciences

2020, Doug Martin, College of Veterinary Medicine

2019, Rex Dunham, College of Agriculture

2018, David Ketchen, Raymond J. Harbert College of Business

2017, James Barth, Raymond J. Harbert College of Business

2016, Hanqin Tian, College of Forestry, Wildlife and Environment

2015, Bruce Tatarchuk, Samuel Ginn College of Engineering

2014, Geoffrey Hill, College of Sciences and Mathematics

2013, Pradeep Lall, Samuel Ginn College of Engineering

2012, Christopher B. Roberts, Samuel Ginn College of Engineering

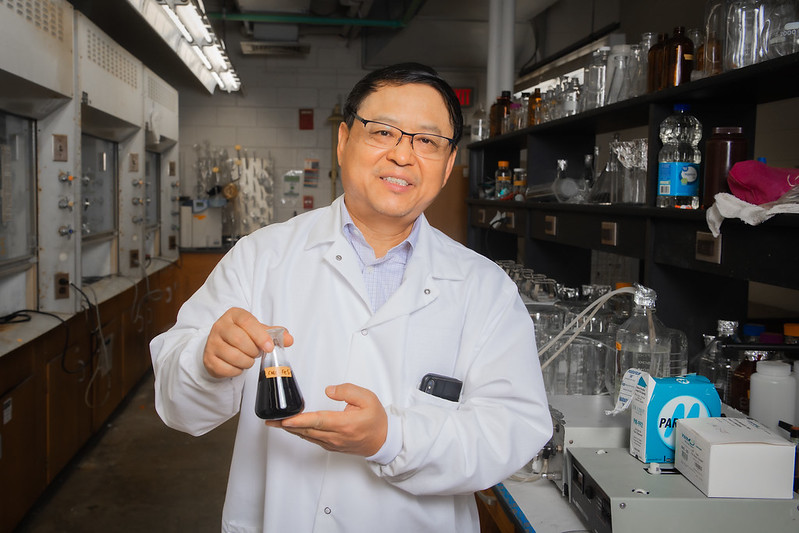

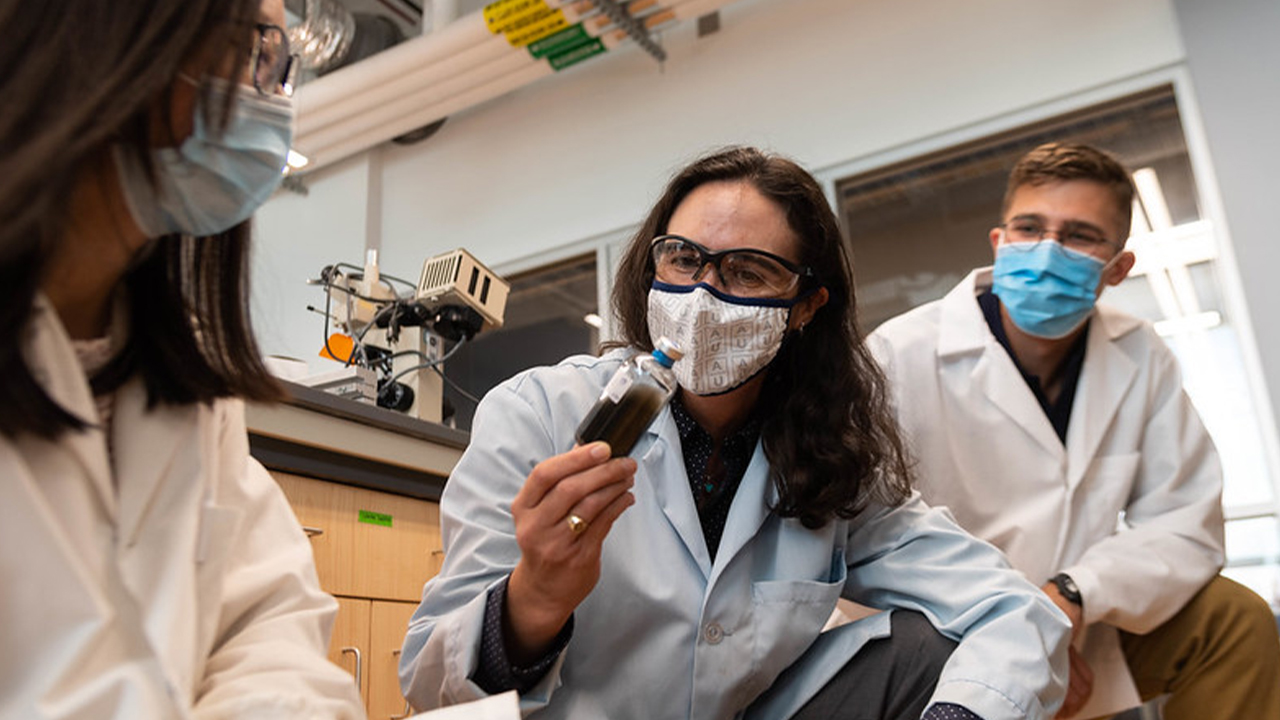

Sushil Adhikari holds paper-like biochar. Even in this form, biochar can be used to enhance soil and plant health.

Categories: Engineering, Energy & the Environment, Agriculture

Pettus named executive director of Auburn University Applied Research Institute in Huntsville

Auburn University’s Office of the Senior Vice President for Research and Economic Development has hired Jonathan Pettus as executive director of the Auburn University Applied Research Institute (AUARI) in Huntsville, effective February 1.

Pettus previously worked for 27 years at NASA, where he served in a variety of executive leadership roles including as NASA’s chief information officer and as the associate director of Marshall Space Flight Center. Before joining the Auburn family, he retired from Dynetics/Leidos, where he led a business unit that included programs in space, hypersonics and cybersecurity solutions.

Beginning his career as a high school mathematics teacher and basketball coach, Pettus grew up “intrigued and enthusiastic about space” and technology, he said. Pettus noted he is “excited about the opportunity to help with the overall strategic goal of continuing to grow Auburn’s impact in applied research” and sees a “great opportunity” at AUARI to grow research efforts aimed at solving real-world problems.

“The Applied Research Institute will be in capable hands with Jonathan Pettus as its executive director,” said Steve Taylor, senior vice president for research and economic development. “He brings to the position a wealth of knowledge and experience in the aerospace, defense and advanced technology sectors. I am confident he will help us expand critical applied research efforts that will address important challenges from our government and industry partners.”

The Auburn University Applied Research Institute operates within the Auburn University Research and Innovation Campus in Huntsville's Cummings Research Park near the Redstone Arsenal, a 38,000-acre federal research, development, test and engineering center. The Institute brings together Auburn faculty, research professionals, and students to conduct cutting-edge applied research and development across a range of technology readiness levels to help customers overcome aerospace, defense, national security and biotechnology challenges.

Media Contact: Jeremy D Henderson, jdh0123@auburn.edu, 334-844-3591

Jonathan Pettus has been named executive director of the Auburn University Applied Research Institute. [Credit: UAH]

Categories: Engineering, Transportation, Manufacturing, OSVPRED

Assistant professor in chemical engineering wins NSF CAREER Award

Driven by evolving technological needs, consumer preferences, environmental concerns and regulatory requirements, the $100-plus billion coatings industry has a growing need to develop new products.

Michael Howard, an assistant professor in chemical engineering, offers a promising solution: a computer-modeling approach to engineer the drying-induced assembly of colloidal-particle coatings, such as paint. This innovative method could streamline production, saving time and reducing resource consumption.

“The outcome of this research could empower scientists and engineers to understand and design the materials and processes needed to reformulate coatings, shortening the research and development cycle in both academic and industrial settings,” Howard explained.

Howard earned a five-year, $500,000 National Science Foundation (NSF) CAREER Award for his project, “Multiscale modeling for self-assembly of colloidal-particle coatings with gradient compositions.”

The NSF’s Faculty Early Career Development (CAREER) Program is one of the foundation's most prestigious awards, supporting early career faculty who have the potential to serve as academic role models and lead advances in their fields.

“I'm excited and humbled to receive this award because it uniquely recognizes both research and teaching,” Howard said. “The reason why I wanted to become a professor is that I enjoy both, so winning this award to support and recognize my work in those areas is really meaningful to me.”

Selen Cremaschi, chair of the Department of Chemical Engineering, praised Howard for his innovative and impactful research.

“Dr. Howard is committed to his students’ education and success and driven to contribute to solving complex challenges. Our department is very proud of Dr. Howard, and we are thrilled that his integrated research and teaching career plans are recognized by this prestigious award,” Cremaschi said. “Winning the prestigious NSF CAREER Award further

highlights his outstanding achievements and underscores his promise as a leading researcher.”

Howard’s modeling approach will predict the composition of colloidal-particle coatings made by solvent drying with unprecedented accuracy using a combination of 1) a physics-based continuum model with realistic particle interactions and hydrodynamics, 2) a machine-learned model, trained from particle-based simulations, to refine the physics-based model and 3) a surrogate model to relate particle properties and processing conditions to composition.

“My long-term research goal is to computationally design nanomaterials and processing strategies for making functional soft materials using my unique background in statistical thermodynamics, transport and high-performance computing,” Howard said. “Achieving the objective of this project will position me not only to design coatings but also to apply similar techniques to other nanomaterials and processes.”

The coatings industry might not be the only beneficiary. Howard’s students are, too.

Howard will integrate research with education through virtual-reality (VR) activities on nanoscale engineering. Specifically, his research will be used to create immersive visualizations that enrich learning about nanoscale concepts that are otherwise challenging to demonstrate.

These activities will be tailored for a wide range of learners, including K–12 students, undergraduates, and the public. To support this, Howard will develop a new VR visualization platform, focusing on sustainability, ease of creating activities and accessibility for learners with different levels of technology.

Howard’s proposed VR platform will include:

- A VR visualization tool that delivers a high-quality educational experience on both state-of-the-art headsets and commodity cell phones. This tool will ensure VR activities can be used with large groups of students and those with less access to computing resources.

- A framework for creating activities that doesn’t require advanced programming knowledge and a curated activity repository. This framework and repository will facilitate content creation by experts and adoption by non-experts.

“(Assistant professor) Symone Alexander and I piloted the use of VR activities with Auburn chemical engineering students through an AUX: Immersive Learning Experiences grant from the Biggio Center. Our students responded really positively, so I’m excited to build on that success and bring this emerging technology to a wider community.”

Additionally, Howard's project aims to broaden participation in STEM activities through undergraduate research opportunities, train a more competitive U.S. workforce in computational science and develop and disseminate open-source scientific software.

Media Contact: Joe McAdory, jem0040@auburn.edu, 334.844.3447

Michael Howard

Categories: Engineering

Auburn rocket plume research to aid future spacecraft landings

Landing a space vehicle on an interplanetary body has always been a tremendous challenge. In most cases, powerful retrorockets must fire at just the right moment — with just the right amount of thrust — to slow the vehicle sufficiently to prevent damage and successfully deliver the payload to the target’s surface. That’s why touchdown is always a hold-your-breath moment for the scientists and engineers involved.

Even so, landing successfully is only one part of the battle. The other part is ensuring the dust and debris kicked up by the retrorocket’s thrusters do not damage the vehicle itself or any other important hardware nearby. But a team of Auburn researchers are working to reduce some of the stress during landings by studying these thruster-induced plume-surface interactions (PSI) to better predict their outcomes.

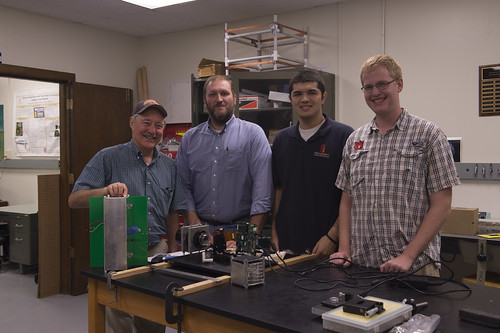

David Scarborough, an associate professor in the Department of Aerospace Engineering at Auburn University, is the principal investigator for two NASA grants — one for $538,789 and a second for $650,000 — to study PSI, along with a team that also includes co-investigators and fellow faculty, associate professor Vrishank Raghav, assistant professor Nek Sharan and the W. Allen and Martha Reed Professor and department chair Brian Thurow. In addition, the research team also includes postdoctoral fellow Vikas Bhargav and graduate students, Murphy Mitchell, Srijan Satyal and Brandon Fulone. In the past, graduate students, Trevor Crane, Daniel Stubbs and Lokesh Silwal were also actively involved in the experimentation work.

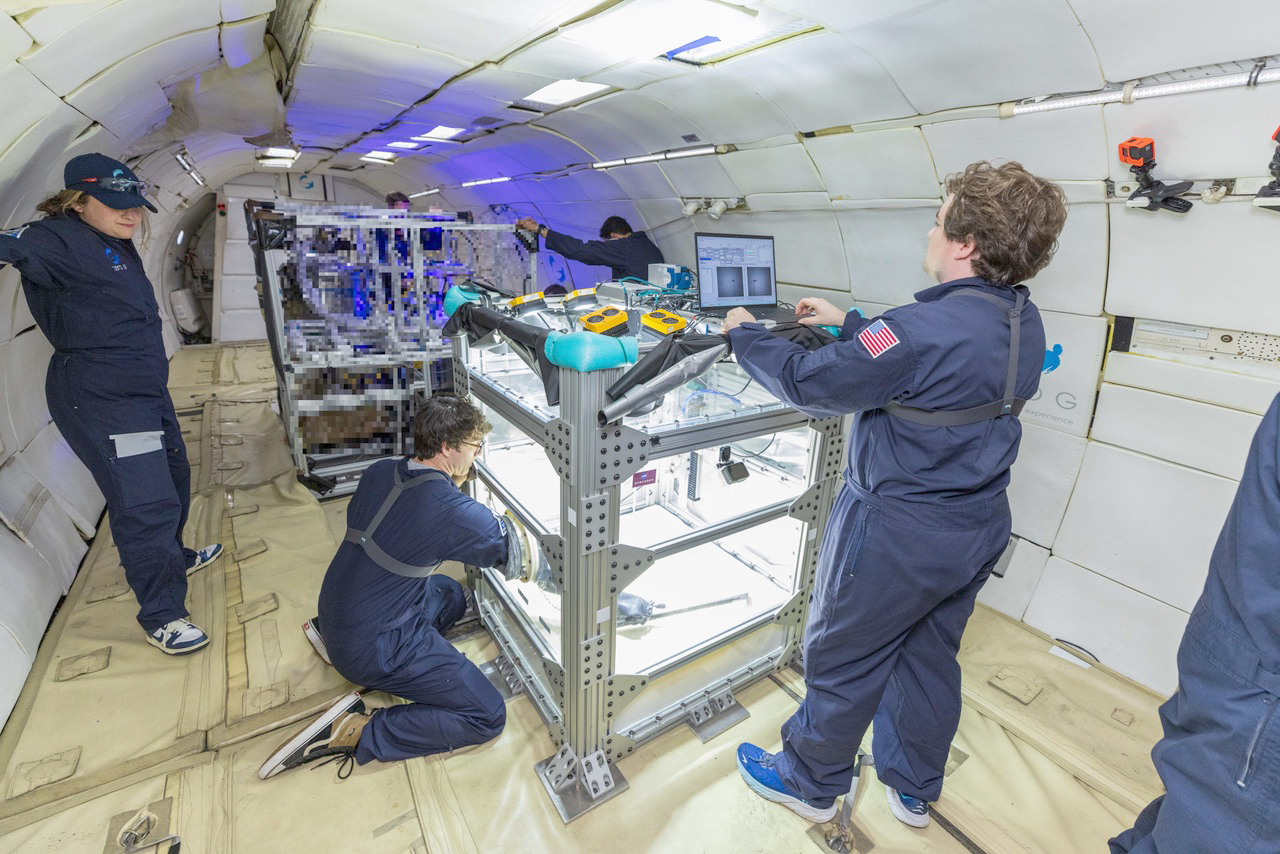

Graduate students Trevor Crane (kneeling) and Daniel Stubbs (standing over the equipment) conduct experiments aboard the "Vomit Comet.

NASA’s interest in PSI dates back as far as the lunar missions of the Apollo Program in the 1960s. Research into the issue gained urgency after the Apollo 12 mission in November 1969. On that mission, the lunar module set down adjacent to the lander from a previous 1967 unmanned mission called Lunar Surveyor Three, which had sent back data critical to planning the Apollo landings. The Apollo 12 astronauts brought back pieces of the Surveyor craft, which showed pitting and scorch marks caused by the retrorockets fired during the lunar module’s descent.

With NASA now planning a return of manned missions to the moon in the near future, better understanding plume-surface interactions will be critical to ensuring such damage can be predicted and perhaps mitigated.

“In the next decade,” Scarborough said, “NASA is prioritizing returning humans safely to the moon, deploying scientific instruments on a variety of extraterrestrial bodies and ultimately enabling human exploration of Mars. One of the most significant obstacles to achieving these objectives is our limited understanding of plume-surface interactions leading to crater evolution and dust formation during descent and touchdown.”

In order to improve our understanding of PSI, experimental facilitates have been constructed in the Auburn University Combustion Physics Laboratory (AUCPL) to emulate conditions of extraterrestrial environments that future landers might encounter.

For instance, the vacuum-chamber experimental facility is used to simulate lunar atmospheric conditions, while the drop-tower facility can generate reduced gravity conditions. These facilities were used to record the crater evolution and track ejecta particles using high-speed cameras, to investigate the effects of the thruster operating conditions and the ambient environment.

In spring 2024, Crane and Stubbs took the research even further, designing and conducting experiments on board NASA’s modified Boeing 727 aircraft — nicknamed “the Vomit Comet” — that flies parabola patterns designed to briefly produce lunar, Martian and zero-gravity conditions.

“Depending on the angle at which the plane falls, different gravity levels are simulated inside the cabin,” Crane explained, noting that the aircraft really lives up to its nickname. “In the airplane, we are able to run our PSI experiments in simulated Martian, lunar and micro-gravity conditions. Research using the parabolic flights is ongoing, with future flights planned to gather more data.”

In the recent past, NASA also conducted an experimental campaign called physics-focused ground tests to fundamentally characterize plume-surface interactions. These tests generated substantial datasets, which require a long-term, dedicated effort to deduce important physics involved in the interactions. The team at Auburn also aims to leverage the experimental and numerical capabilities in-house to facilitate the development and validation of predictive tools using the datasets generated by NASA.

Eventually, the team hopes to provide NASA with data that will allow the space agency to confidently predict and make allowances for plume-surface interactions on the moon, Mars and beyond.

“The overall goal of our PSI research is to be able to develop physics-based models for rocket landers that can be used for future missions,” Scarborough said. “These models will be able to relate to parameters like rocket size, engine thrust and dust or particle size of the planetary surface to predict the cratering and debris effects caused by a lander. Future simulations will be able to use these models to better inform lunar and Martian missions and reduce the risks associated with their landing vehicles.”

David Scarborough, an associate professor in the Department of Aerospace Engineering at Auburn University (middle), stands with graduate students Daniel Stubbs (left) and Trevor Crane (right).

Categories: Engineering, Transportation

Auburn materials engineering students have MXene research down to a fine art

At this rate, Auburn may need to open its own "NanoArt" museum. Because the Department of Materials Engineering just keeps churning out masterpieces.

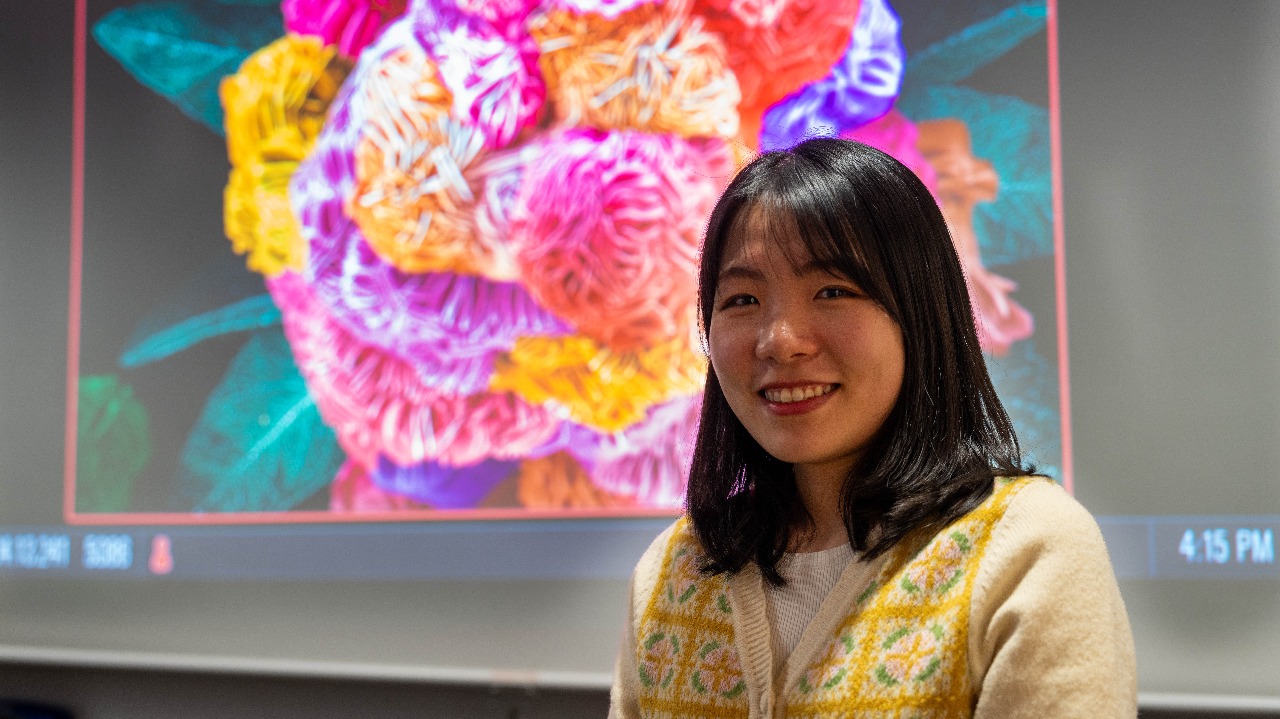

The latest award-winning contribution comes, once again, courtesy of microscope maestro Yeonjin Baek, one of the department's most recent doctoral graduates, and rising star of the so-called NanoArt competition circuit created by engineers and scientists celebrating the surprisingly artistic aspects of their research. Her medium? Once again, MXenes — a still relatively new class of 2D conductive crystalline nanomaterials promising battery storage breakthroughs, like giving your iPhone a full-day's charge in seconds or supplying juice to supercapacitors for millions of charging cycles.

Otherworldly images mined from MXenes have quickly become go-to graphics for NanoArt competitions since they were discovered at Drexel University in 2011; it turns out that, combined with a little Photoshop creativity, the results of throwing slices of, say, vanadium carbide under scanning electron microscopes (SEMs) can be downright stunning.

A year ago, Baek took home the grand prize in Japanese research technology company JEOL's annual scanning SEM image contest for a scan of a synthesized Vanadium oxide nano structure. Imagine a bouquet of flowers painted by impressionist Édouard Manet, but with the nearly unfathomable resolution of the materials engineering department's $500,000 JEOL JSM-7000F SEM).

Months later, her "MXene T-Rex," a scan of a layered niobium carbide resembling a Tyrannosaurus Rex 10 times smaller than the width of a human hair, won the October round of the same contest. Most recently — and, in terms of reflecting Auburn's rising materials engineering preeminence, perhaps most impressively — it placed second out of 300 submissions from 29 countries in the 9th annual NanoArtography competition sponsored by Purdue University's School of Materials Engineering and Drexel University's Nanomaterials Institute.

"I believe that materials engineering is essential for driving technological progress," said Baek, who recently accepted a postdoctoral research position at the University of Arizona. "What fascinates me most is how we can manipulate materials at the micro and nanoscale to innovate and improve various devices like electric vehicles and batteries.

"When we synthesize materials, they often appear as nothing more than dark gray or black powders. However, when observed under a microscope, we can uncover beautiful layered structures or unique nanoscale patterns. Materials like MXenes exhibit delicate accordion-like layered structures that make them particularly ideal for NanoArt. These structures showcase the texture and beauty of the nanoscale, providing a perfect canvas for creative interpretations."

Thanks the Department of Materials Engineering, Auburn's reputation for creative interpreations of the nanoscale has been at macro proportions for years.

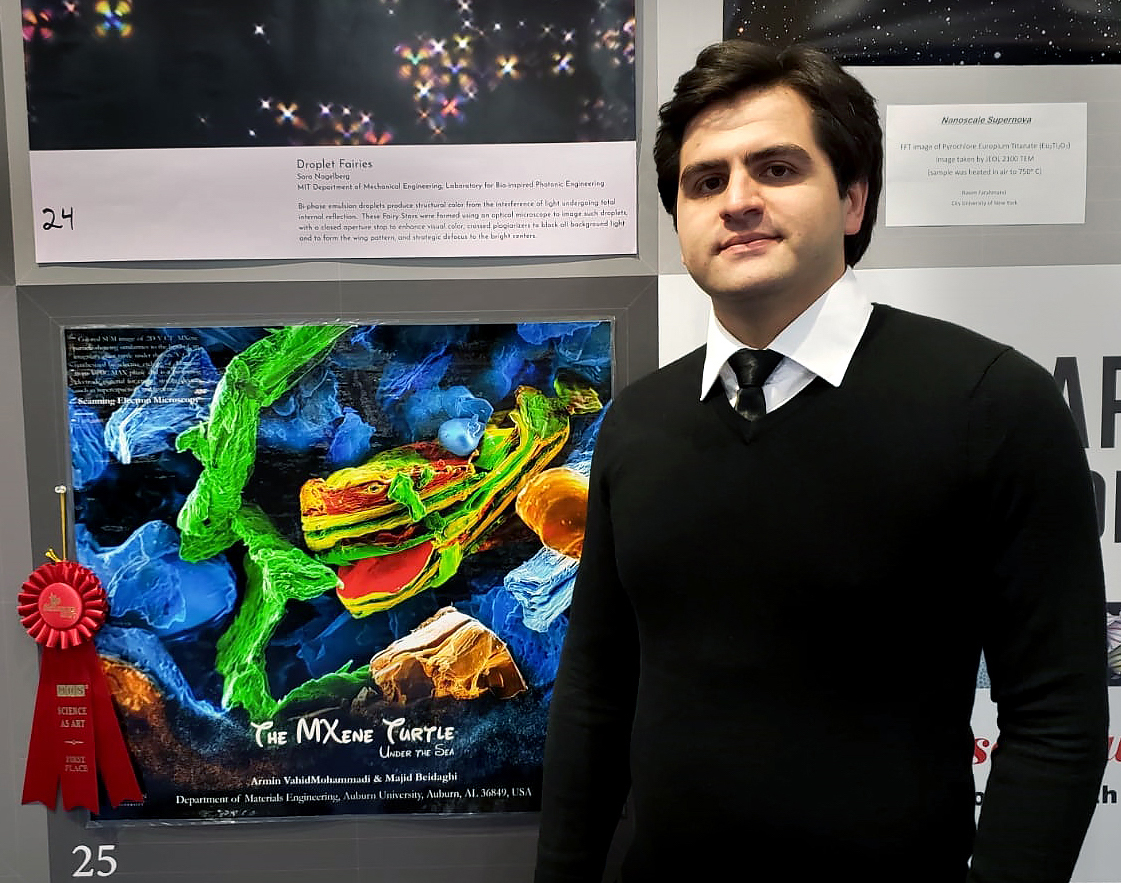

Armin VahidMohammadi poses with "The MXene Turtle Under the Sea," which won First Place in the 2018 MRS Science as Art competition.

Baek was actually Auburn's second grand prize winner in the JEOL contest. In 2017, materials engineering doctoral student Armin VahidMohammadi, who is now in product development at Tesla, snagged the blue ribbon with "Nano Nemo on the Water," a scan of a MXene designated Ti2C modified to resemble a clown fish. It was his second conquest in an epic string of victories that gained attention even outside the scientific community for primarily playing on pop culture.

A year before he found Nemo in titanium carbide, the avid Harry Potter fan's wildly vivid "Nano Lord Voldemort" placed first in the Materials Research Society’s Science as Art competition, an accomplishment repeated in 2018 after spotting "The MXene Turtle Under the Sea" in clouds of vanadium carbide. For his 2019 entry, he again used the force of the material engineering department's JSM-7000F to produce "MXene Yoda," a scan of oxidized 2-D V2CTx particles.

Win again, he did.

"It's been great for our students to receive this sort of attention for their creativity," said materials engineering program chair Bart Prorok, Baek's faculty advisor. "But I'd like to think it also reflects rather favorably on the research our department excels in. Right now a lot of that research is, obviously, in MXenes.

And, right now, Auburn students obviously have that research down to a fine art.

"While Armin was here, his research on MXenes was featured in Advanced Materials, which is a pretty prestigious journal," Prorok said. "But even though you could look at the nano artwork as a kind of novelty, thousands of materials scientists pay attention to a lot of these competitions. So, the artwork he and now Yeonjin have done has definitely helped us gain attention on our research, and it's attention I think Auburn deserves."

Media Contact: Jeremy D Henderson, jdh0123@auburn.edu, 334-844-3591

Yeonjin Baek poses in front of a display of "Flower Power," which won the grand prize in JEOL'S 2023 SEM Image Contest.

Yeonjin Baek's, "MXene T-Rex," a scan of a layered niobium carbide resembling a Tyrannosaurus Rex 10 times smaller than the width of a human hair

Categories: Engineering, Creative Scholarship

Auburn University Gulf Coast Engineering Research Station in Orange Beach receives final Board of Trustees approval

Auburn University’s Board of Trustees gave its final approval Friday for the construction of a Gulf Coast Engineering Research Station in Orange Beach.

The two-story, 21,000-square-foot facility — to be located at 4775 Walker Avenue — will provide direct access to the Gulf of Mexico and consist of research laboratories, offices, large meeting spaces and outdoor gathering spaces on both stories of the south elevation overlooking Terry Cove. The station will provide a dedicated location for researching coastal environments and communities of the Gulf Coast while also providing opportunities for collaboration with other Marine Environmental Sciences Consortium institutions.

“We are thankful to the board for its continued support of this project that will benefit Auburn University, the state’s coastal communities and those who love and visit one of the most beautiful areas of this state,” said Mario Eden, dean of Auburn’s Samuel Ginn College of Engineering. “The opportunity for collaboration with our friends and partners in the city of Orange Beach, the University of South Alabama and other regional institutions and industries is exciting, and this gives us a home base to address some of the most pressing coastal issues related to infrastructure resiliency and environmental protection, restoration, sustainability and conservation.”

The estimated total project is $14 million, and it is being financed by grant funds from the RESTORE Council in cooperation with the State of Alabama Department of Conservation and Natural Resources. The city of Orange Beach provided the land for the project.

The Board of Trustees initially approved the facility at its September 2022 meeting. The firm ArchitectureWorks was approved in November of that year to serve as the architect on the project.

Orange Beach Mayor Tony Kennon said the city is proud to work with Auburn and other universities to create long-term solutions for the state’s Gulf Coast, and beyond.

“As I’ve said from the onset of this collaborative project, the city of Orange Beach is excited about the opportunity to partner with Auburn University and work with universities all over the country for the betterment and preservation of our vital coastal resources,” Kennon said.

The gulf station will focus on three broad coastal research areas: water quality and quantity protection and restoration; protection, restoration and conservation of habitat and living resources; and enhancing coastal community sustainability and resilience. In addition, it will also provide residents and visitors with a better understanding and appreciation of the natural, historical, cultural and environmental resources of the region through community outreach and continuing education opportunities.

Effects of natural and man-made disasters on the primary industries in the region have resulted in economic adjustments and dislocations primarily through reductions in tourism and the simultaneous effects on tourism-related industries; damage to public and private infrastructure; negative impacts to agriculture and fishing-related industries; and damage to the natural environment and natural resources.

Through the creation of this facility, Auburn University and its partners will engage in fundamental and applied research of critical importance to the coastal environment and communities of Alabama and the larger northern Gulf Coast region. The station will be dedicated to addressing all the goals and objectives set forth in the 2016 Gulf Coast Ecosystem Restoration Council Comprehensive Plan.

Media Contact: Austin Phillips, austinp@auburn.edu, 334-844-2444

Auburn University’s Board of Trustees gave its final approval Friday for the construction of a Gulf Coast Engineering Research Station in Orange Beach.

The two-story, 21,000-square-foot facility — to be located at 4775 Walker Avenue — will provide direct access to the Gulf of Mexico and consist of research laboratories, offices, large meeting spaces and outdoor gathering spaces on both stories of the south elevation overlooking Terry Cove. The station will provide a dedicated location for researching coastal environments and communities of the Gulf Coast while also providing opportunities for collaboration with other Marine Environmental Sciences Consortium institutions.

“We are thankful to the board for its continued support of this project that will benefit Auburn University, the state’s coastal communities and those who love and visit one of the most beautiful areas of this state,” said Mario Eden, dean of Auburn’s Samuel Ginn College of Engineering. “The opportunity for collaboration with our friends and partners in the city of Orange Beach, the University of South Alabama and other regional institutions and industries is exciting, and this gives us a home base to address some of the most pressing coastal issues related to infrastructure resiliency and environmental protection, restoration, sustainability and conservation.”

The estimated total project is $14 million, and it is being financed by grant funds from the RESTORE Council in cooperation with the State of Alabama Department of Conservation and Natural Resources. The city of Orange Beach provided the land for the project.

The Board of Trustees initially approved the facility at its September 2022 meeting. The firm ArchitectureWorks was approved in November of that year to serve as the architect on the project.

Orange Beach Mayor Tony Kennon said the city is proud to work with Auburn and other universities to create long-term solutions for the state’s Gulf Coast, and beyond.

“As I’ve said from the onset of this collaborative project, the city of Orange Beach is excited about the opportunity to partner with Auburn University and work with universities all over the country for the betterment and preservation of our vital coastal resources,” Kennon said.

The gulf station will focus on three broad coastal research areas: water quality and quantity protection and restoration; protection, restoration and conservation of habitat and living resources; and enhancing coastal community sustainability and resilience. In addition, it will also provide residents and visitors with a better understanding and appreciation of the natural, historical, cultural and environmental resources of the region through community outreach and continuing education opportunities.

Effects of natural and man-made disasters on the primary industries in the region have resulted in economic adjustments and dislocations primarily through reductions in tourism and the simultaneous effects on tourism-related industries; damage to public and private infrastructure; negative impacts to agriculture and fishing-related industries; and damage to the natural environment and natural resources.

Through the creation of this facility, Auburn University and its partners will engage in fundamental and applied research of critical importance to the coastal environment and communities of Alabama and the larger northern Gulf Coast region. The station will be dedicated to addressing all the goals and objectives set forth in the 2016 Gulf Coast Ecosystem Restoration Council Comprehensive Plan.

Media Contact: Austin Phillips, austinp@auburn.edu, 334-844-2444

The two-story, 21,000-square-foot facility — to be located at 4775 Walker Avenue — will provide direct access to the Gulf of Mexico and consist of research laboratories, offices, large meeting spaces and outdoor gathering spaces on both stories of the south elevation overlooking Terry Cove.

Categories: Engineering, Energy & the Environment, Gulf of Mexico Research & Restoration

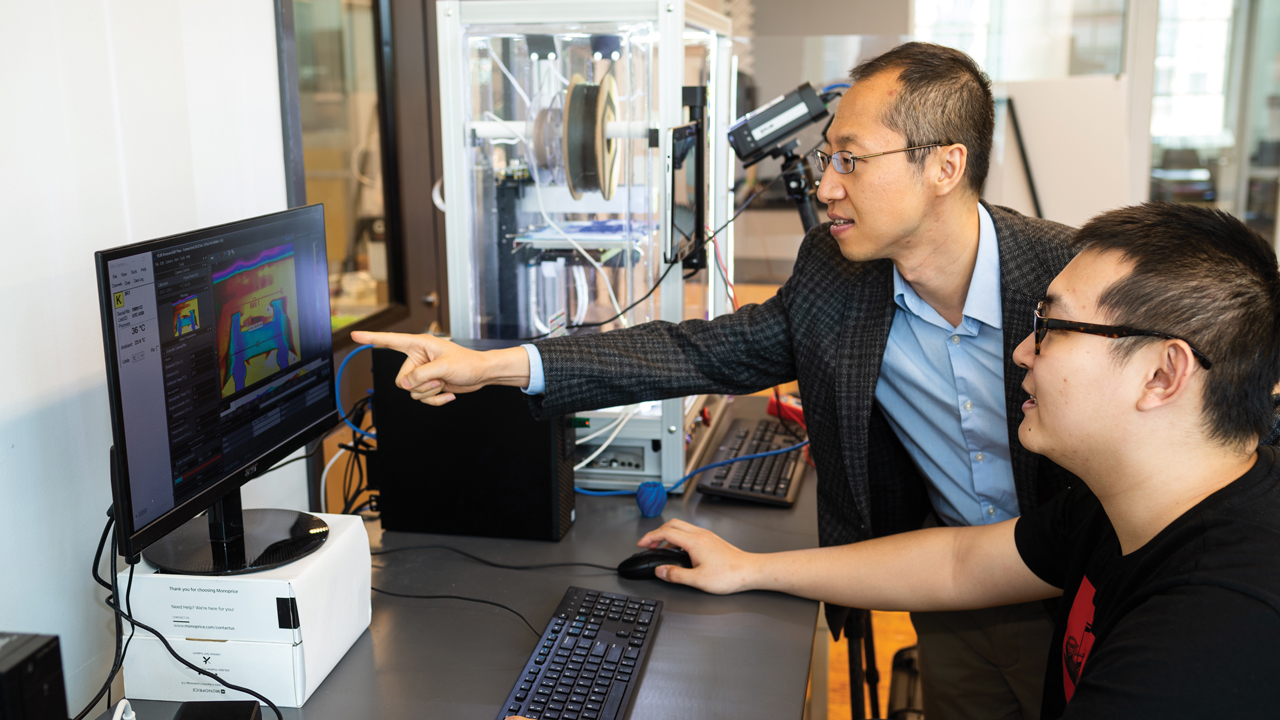

Auburn Engineering’s additive manufacturing research is key component in NASA’s Invention of the Year

Auburn's work on the high-tech hardware that will take people to Mars has earned some impressive hardware of its own.

Researchers in Auburn University's National Center for Additive Manufacturing Excellence (NCAME) continue to play a critical role in the Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) project, specifically the project's resulting Thrust Chamber Liner and Fabrication Method technology which, in July, was named NASA's 2024 Invention of the Year.

“This is another in a long list of big achievements for the RAMPT team,” said John Vickers, NASA’s principal technologist for additive manufacturing. “Along with industry partners and with support from NASA’s Game Changing Development Program, Auburn has helped create transformative manufacturing technology that will impact the nation’s space economy.”

NCAME's work on RAMPT, which began in 2019 under a NASA contract now totaling $22 million, involves heat treatment development, materials characterization and structural integrity assessment over a wide range of temperatures aimed at evolving light-weight, large-scale novel additive manufacturing (AM) techniques for the development of regeneratively-cooled thrust chamber assemblies for large-scale liquid rocket engines; few, if any, research labs in the world are better equipped to evaluate the microstructure property relationships in the AM metallic material used for that type of propulsion hardware design.

NCAME's contributions to RAMPT also include the facilitation of a domestic supply chain and specialized manufacturing capabilities available to the government, academic and commercial entities collaborating on the project.

In 2021, the center's expertise factored heavily into the production of a 10-foot tall, 2-ton additively manufactured rocket nozzle liner used by NASA to demonstrate RAMPT's efficacy — likely the largest such component in the world — built in conjunction with leading national metal additive manufacturing firms.

Though the nozzle liner was a significant milestone, NCAME director Nima Shamsaei, principal investigator for Auburn's work on RAMPT, finds the Invention of the Year Award particularly validating — and meaningful.

"NCAME was formed in 2017 through a partnership between Auburn University and NASA, and RAMPT was one of our early marquee projects," Shamsaei said. “That was due largely to the work of Mike Ogles, who was a co-Pi. I know he’d be proud of the award.”

Ogles, a 1989 Auburn mechanical engineering graduate and former director of NASA programs in the Samuel Ginn College of Engineering, passed away in October 2021 after a six-month battle with cancer. Working primarily behind the scenes, his connections with NASA’s Marshall Space Flight Center in Huntsville were instrumental in securing several major research contracts and partnerships for the college — RAMPT chief among them.

Shamsaei also credited co-PI Steve Taylor, senior vice president for research and economic development, as well as Shuai Shao, NCAME’s associate director for research and innovation, research engineer Tom Hill, program administrator Samantha Allbrook, and Kelley Terry, director of the Samuel Ginn College of Engineering’s office of Research Administration.

“The project’s success is due to the efforts of a great team led by NASA, NCAME and our private sector AM technology partners,” Taylor said. “Their work went a long way toward establishing Alabama as the go-to state and Auburn as the go-to university for AM research and development. And, obviously, in terms of solidifying NCAME's international reputation as an AM authority, it will pay dividends long into the future.”

Media Contact: Jeremy Henderson, jdh0123@auburn.edu, 334-844-3591

This 2-ton, additively manufactured RS25 nozzle liner — the largest component of its kind in the world — was printed in 2021 on the strength of Auburn Engineering research conducted through NASA's RAMPT program.

Categories: Engineering, Transportation, Advanced Systems

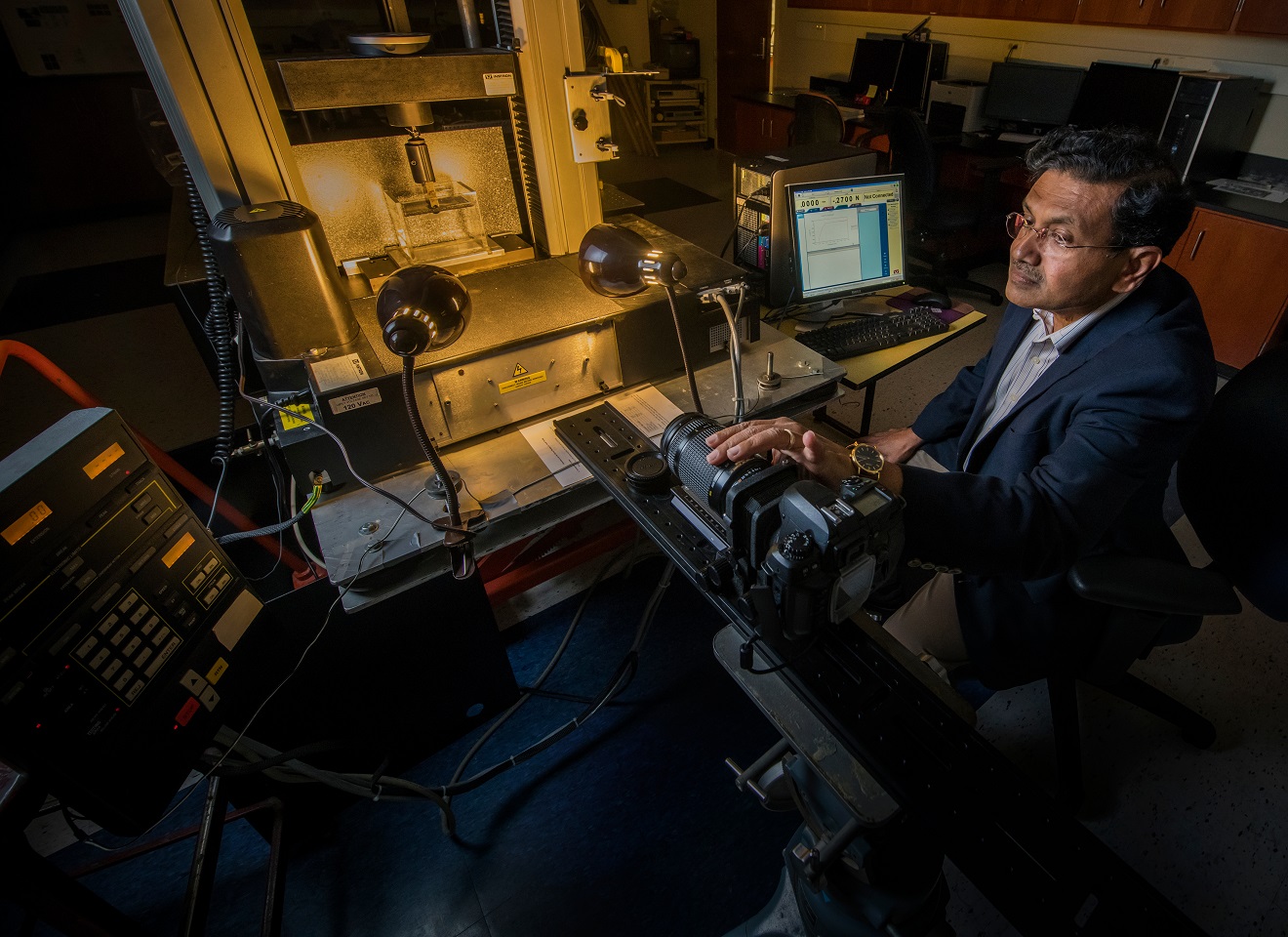

Auburn establishes Electronics Packaging Research Institute

Auburn University's seminal work on semiconductor packaging has new packaging of its own — the Auburn University Electronics Packaging Research Institute (EPRI).

The institute’s recent establishment marks a significant new emphasis on the semiconductor packaging research conducted through Auburn's Center of Advanced Vehicle and Extreme Environment Electronics, or CAVE3, which was founded in 1999 through funding from the National Science Foundation and support from select companies focusing primarily on automotive electronics.

Pradeep Lall, John and Anne MacFarlane Endowed Distinguished Professor and Alumni Professor in the Department of Mechanical Engineering, has directed the center since 2008. He will continue to serve as director of EPRI.

“Our need for domestic capability in manufacturing, research and development for semiconductor packaging has really entered the national conversation recently with the recent establishment of the National Advanced Packaging Manufacturing Program (NAPMP) under the Creating Helpful Incentives to Produce Semiconductors — or CHIPS — Act,” Lall said.

In June 2021, the White House identified four key product areas of vulnerability, with semiconductor manufacturing and advanced packaging topping the list.

The report recognized the role of semiconductor packaging as an important avenue for innovation in the density and size of electronic products; the U.S. global share of semiconductor production has dropped from 37 percent in 1990 to only 12 percent today.

“In this current environment, we’re realizing the criticality of electronics in general and semiconductor packaging in particular for securing the supply chain and enabling advanced system functionality both in the U.S. and Europe,” Lall said.

Under Lall’s leadership, Auburn’s work along these lines has grown exponentially, especially over the past decade.

In 2015, he led the Auburn team contributing to the winning proposal that resulted in the foundation of the NextFlex National Manufacturing Institute. Auburn is a tier-1 founding member of NextFlex, whose mission is to advance U.S. manufacturing of flexible hybrid electronics; Lall serves on the NextFlex technical council and has previously served on the governing council of the institute.

“Growing CAVE3 into the Auburn University Electronics Packaging Research Institute was the logical next step for our activities in this important area of research," said Dean of Engineering Mario Eden. "It's recognition of its broadened focus, breadth of sponsored research, as well as its international standing.”

Steve Taylor, senior vice president for research and economic development, agrees.

"This expansion reflects not only Auburn's ever-widening range of research areas, but it will also increase the resources and capabilities to further our mission of advancing electronics packaging technologies and solidifying our reputation as a global leader in the field," Taylor said.

In accordance with its expanded scope, EPRI will partner with several campus offices and colleges, including the Auburn University Research and Technology Park (ARTP), the College of Science and Mathematics, the Samuel Ginn College of Engineering and the Auburn Office of AVP Economic Development.

EPRI will interface with ARTP for technology commercialization, and with small and medium-sized companies across the state and nation for education pertaining to workforce development. Economic Workforce Development (EWD) will be explicitly pursued in the field of electronic packaging through an interface with the Office of AVP of Economic Development.

“We look with excitement to the future as Auburn University, through EPRI, looks to contribute to the national focus on advanced electronics manufacturing with a broader emphasis on workforce development, new product launch and technology commercialization,” Lall said.

Media Contact: Jeremy Henderson, jdh0123@auburn.edu, 334-844-3591

Pradeep Lall, the MacFarlane Endowed Distinguished Professor and Alumni Professor of mechanical engineering, displays an in-mold galvanic skin response sensor for automotive applications additively manufactured at the Auburn University Electronics Packaging Research Institute.

Categories: Engineering, Advanced Systems

Can a helicopter safely land after engine failure? Researcher earns $307K grant to explore how

Turbine helicopter engines fail once every 375,000 flight hours according to the Federal Aviation Administration. Which control sequences and flight conditions make it possible for trained pilots to land in the event of engine failure? Which conditions do not?

Matthew Kirchner, assistant professor in electrical and computer engineering, will soon find out.

Sponsored by the Office of Naval Research, his three-year, $307,000 study, “Safe Flight Envelope Characterization and Emergency Landing with Reachability,” will create height-velocity diagrams (H-V diagrams) for various helicopter models — guides for pilots to handle emergency landings and investigate reliable engine failure detection techniques.

“It’s rewarding to have the opportunity to provide the Navy with important information that could reduce the number of potential accidents and keep our pilots safe,” said Kirchner, who spent 16-plus years as a research scientist at the Naval Air Warfare Weapons Division in China Lake, California, before joining the faculty at Auburn University this past fall.

Kirchner’s research will distinguish “safe regions” from “unsafe regions” when pilots undergo emergency landings. Safe regions are defined as “any initial flight condition where there exists a control sequence that can steer the system (manned or unmanned) to a safe landing condition.” Unsafe regions are conditions where no such control sequence is available and a safe landing is impossible.

Engine failure doesn’t immediately lead to rotor failure. Like a common ceiling fan, momentum allows blades to spin for a short time after power failure. Kirchner referred to this phenomenon as “autorotation.”

Kirchner will create control sequences via H-V diagrams to initiate an autorotation, whereby the helicopter enters a glide slope to maintain rotor inertia before safely touching down.

“The pilot can still move the helicopter forward based on inertia and the angular momentum of the blades,” said Kirchner, whose research also applies to unmanned rotorcraft. “Helicopters can change the pitch of the blades as they’re spinning. When there is no engine power at all, one must be careful. If you have too much pitch, the pilot might delay the sink rate but will also eat up much of that angular momentum.

“You’re falling, but if you do it the right way, you can keep the blade spinning and could have enough energy left over to flare the helicopter and touch the ground safely. Pilots must find that sweet spot. If you lose energy at some point… you’re toast.”

Kirchner will utilize scaled radio-controlled rotorcraft on test fields near Auburn University and the Manned Flight Simulator Facilty – a high-fidelity, man-in-the-loop research/development test and evaluation flight simulation laboratory at the Naval Air Warfare Center Aircraft Division in Patuxent River, Maryland.

“H-V diagrams are ultimately determined through flight testing, which is inherently dangerous since the test objective is to define the unsafe boundaries of flight operations,” Kirchner said. “Therefore, there is a need to accurately compute the safe and unsafe regions directly from the helicopter dynamics and construct a H-V diagram prior to flight testing.

“The Navy needs to have information it can give to pilots that says, ‘we might have a safer region over here,’ or ‘it’s best to minimize another region over there. We must update pilots in real time to know where they can account for these factors and be able to tell them precisely how they can execute specific maneuvers.”

Kirchner is joined on the project by Jacques Hoffler, Eddie Ball and Donald Gaublomme from the Naval Air Warfare Center Aircraft Division’s Flight Vehicle Modeling and Simulation Branch.

Media Contact: Joe McAdory, jem0040@auburn.edu, 334.844.3447

Matthew Kirchner will create height-velocity diagrams for various helicopter models — guides for pilots to handle emergency landings and investigate reliable engine failure detection techniques.

Categories: Engineering, Transportation

Eight innovative projects receive 2024 internal awards

Eight innovative projects have been named recipients of Auburn University’s internal research and creative works funding awards programs for 2024.

The Research Support Program (RSP) and the Creative Work and Social Impact Scholarship Funding Program (CWSIS) were established by the Office of the Senior Vice President for Research and Economic Development. Both programs provide a competitive internal funding source to support faculty members’ research and creative scholarship as they refine their projects before competing for larger, external awards.

“The CWSIS and RSP provide applicants across all disciplines with the opportunity to participate in a competitive funding program,” said Christine Cline, associate director of Proposal Services and Faculty Support, the unit administering the programs. “The programs support a wide variety of research initiatives from creative work through STEM-focused projects. We appreciate the opportunity to engage with the participants from the initiation of the application cycle through the successful completion of their projects.”

The RSP is intended to foster the development and growth of innovative and transformational research activities. It builds on faculty expertise, stimulates interdisciplinary collaborations and strengthens seed research activities. It is a strategically focused Auburn investment that promotes promising and impactful new lines of research as well as the growth of collaborative and interdisciplinary teams to build the foundations of science, to overcome scientific and societal challenges and to promote and enhance the quality of life and well-being of individuals, groups and communities.

The CWSIS funding program fosters innovation and discovery and builds faculty reputation and competitiveness. Disciplines associated with CWSIS include design and the arts, humanities and applicable areas within business, education, social sciences and health and well-being.

This year’s recipients are:

Research Support Program

James Gillespie, College of Veterinary Medicine, “Development of Bacteriophage Nano/Microparticles for Nasal Delivery of Species-specific Immunocontraceptives”

Co-Investigator: Constantinos Kyriakis, College of Veterinary Medicine

Suhasini Gururaja, Samuel Ginn College of Engineering, “Integrated Manufacturing for ‘Tuned’ Microstructures for Targeted Enhanced Lightweight Structural Performance and Autonomous Damage Sensing (IMADS)”

Co-Investigator: Virginia Davis, Samuel Ginn College of Engineering

Junshan Lin, College of Sciences & Mathematics, “Computation-assisted Optical Imaging towards Sub-Nanometer Super-resolution”

Co-Investigator: Siyuan Dai, Samuel Ginn College of Engineering

Binita Mahato, College of Liberal Arts, “Urban Resilience and Social Vulnerability: The Past, Present, and Future of Climate Change Impacts in Mobile, Alabama”

Co-Investigators: Chandana Mitra, College of Science and Mathematics; Dr. Jake Nelson, College of Science and Mathematics; Rebecca Retzlaff, College of Liberal Arts

Yaoqi Zhang, College of Forestry, Wildlife and Environment, “Tree Shade on Summertime Electricity Consumption”

Co-Investigator: Wenying Li, College of Agriculture

Creative Work and Social Impact Scholarship Funding Program

Georges Fares, College of Human Sciences, “Bridging Eras: Merging Technology and Tradition in the Study of Bernini’s Works for the Purpose of Cultural Engagement”

Co-Investigator: Anna Ruth Gatlin, College of Human Sciences

Allie McCreary, College of Forestry, Wildlife and Environment, “Climate Change Resiliency Along the Gulf Coast: How Tourism Providers Perceive Impacts & Adaptation Strategies”

Xavier Vendrell, College of Architecture, Design & Construction, “Site, Construction, Users, My Favorite Movies, and Other Circumstances: Xavier Vendrell, Architect”

More information about these and other funding support programs supported by the Auburn Office of the Senior Vice President for Research and Economic Development can be found by clicking here.

Categories: Engineering, Energy & the Environment, Life Sciences, Agriculture, Liberal Arts, OSVPRED, Architecture, Design & Construction

Auburn IPX office, innovative patents, aid continued move up NAI top 100

Auburn University has been ranked among the top 100 U.S. universities granted utility patents in 2023, according to a report published recently by the National Academy of Inventors (NAI).

With 16 new patents issued in 2023, Auburn was ranked 87th on the list, 10 places higher than last year. The list was created to highlight and celebrate American innovation and to recognize those universities that play a large role in advancing the innovation ecosystem within the U.S. and beyond.

A sampling of Auburn’s recent patents demonstrates the wide scope of innovative research ongoing across the university. These include a new aid for use in canine detection training that allows dogs to be taught to alert on extremely hazardous substances without actual risk of exposure to those substances by the dogs or their trainers. Another patent was issued for a low-cost, extremely sensitive sensor — designed to detect a variety of substances — that can be used in a number of inexpensive diagnostic devices.

According to Patrick Reed, who was named executive director of the AU IP Exchange (IPX) Office at the beginning of 2024, the number of patents as well as Auburn’s NAI ranking should only contin

ue to increase thanks to a renewed emphasis on encouraging and incubating innovation across the entire campus.

The IP Exchange, located in Auburn’s Research Park, supports innovation and connects AU subject matter experts with external partners to help bring new ideas and products to market. IPX also moves beyond the traditional technology transfer role by getting involved earlier in the collaborative research process.

“We bring decades of experience evaluating and cultivating early-stage innovation,” Reed said, “and work daily with faculty, staff and students; patents and copyrights; and business, industry and other external partners. Bringing Auburn innovation to the marketplace for the benefit of the public is at the core of everything we do.”

One example of a 2023 patent that is already being brought to the marketplace to benefit the public is a new method for manufacturing personalized protective gear such as pads and braces based on a body scan of the future wearer. An Auburn-based company, XO Armor, is already using this technique — along with advanced 3-D printing technology — to develop individualized athletic and medical devices for clients nationwide. The company was founded by Michael Zabala, Auburn Alumni Engineering Council Associate Professor in the Department of Mechanical Engineering.

And while the university’s STEM areas have traditionally been strong centers of innovation, Reed also noted that the Auburn IPX is increasingly expanding its reach into other colleges and schools campus-wide. The IP Exchange also plans to pursue more federal grant funding opportunities to bolster and increase innovation, commercialization and entrepreneurship across the entire campus.

“We are working to grow the innovation tent at AU by approaching other colleges and schools as well as researchers outside of the usual STEM areas,” he said. “Bringing non-STEM areas into the fold will grow our core metrics while also helping to create new areas of interdisciplinary research, such as inclusion of industrial design or psychology into relevant lines of research inquiry.”

Finally, IPX is working to further improve its services to make them ever more user-friendly. The office has added several new staff members in the past 12 months to further improve the client experience. “Our goal is to make working with IPX as easy as possible,” Reed explained. “We want to be seen as a nimble, flexible, and creative research-support unit.”

All these IPX initiatives promise to continue to add to Auburn’s already strong association with the NAI. In addition to its inclusion on the Top 100 U.S. Universities list, AU has seen nine of its faculty members named as NAI fellows and one as an NAI senior member. The prestigious NAI fellows program honors academicians “who have demonstrated a spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on quality of life, economic development and the welfare of society.”

Current and emeritus Auburn faculty members who have previously been recognized as NAI fellows include Fa Foster Dai, J. David Irwin, Joseph W. Kloepper, John Weete, the late S.D. “Dave” Worley, Bruce Tatarchuk and the late Vitaly Vodyanoy. Auburn faculty member Yonhua Tzeng and Mehmet Arik were named NAI fellows in 2022 and 2023, respectively. Jin Wang, the first Auburn faculty member to be named a senior member, is the Walt and Virginia Woltosz Professor in Auburn’s Samuel Ginn College of Engineering. Wang’s research innovations center around effectively converting waste into value-added products.

Founded in 2010 to recognize and encourage inventors with patents issued from the United States Patent and Trademark Office, the NAI is a member organization of U.S. and international universities and governmental and non-profit research institutes, with more than 4,000 individual inventor members and fellows spanning more than 250 institutions worldwide.

Michael Zabala is one of the patent holders whose innovations earned Auburn a spot in the National Academy of Inventors' ranking of top 100 universities granted utility patents in 2023.

Categories: Engineering, Security, OSVPRED, Economic Development

David named Samuel Ginn College of Engineering associate dean for research

Allan David has been named associate dean for research for Auburn University’s Samuel Ginn College of Engineering, according to an announcement by Dean Mario Eden.

David, the John W. Brown associate professor in the Department of Chemical Engineering, assumes the position effective June 1. He has served as acting associate dean for research since June 1, 2022, when former dean Chris Roberts moved on to become Auburn’s 21st president and then-associate dean for research, Steve Taylor, became interim dean of the college.

“Dr. David has done a tremendous job during the past two years in his role as acting dean of research for the college, and I am thrilled to continue working with him in this permanent role moving forward,” Eden said. “As a college, we have huge aspirations related to our research enterprise, and Dr. David has demonstrated that he has the leadership and forethought to help pave the way to get us there.”

As associate dean for research, David will assist with the college’s strategic planning, budget development, facilities oversight and administration. In collaboration with the dean, David will promote a vibrant research culture by working with department chairs, institute directors and center directors to improve each of their teams’ contribution to the mission of research and scholarship. He will also provide leadership to ensure that processes function effectively for submission of proposals to external sponsors while mentoring, assisting and reviewing proposal development and assisting with technology commercialization activities. Additionally, David will develop and manage research-related policies, research centers and transdisciplinary research within the college, across campus and into industry. He will also play an integral part in developing and implementing the college’s research programs at the Auburn Research Park, the Auburn University Research and Innovation Campus in Huntsville and the soon-to-be-built Gulf Coast Engineering Research Station in Orange Beach.

“The past two years serving as acting associate dean of research has been two of the most rewarding years of my career,” David said. “It opened my eyes to just how truly special this college is, and the impact it is making on the world is immense. Our college is made up of faculty and students who are entrepreneurs, groundbreaking researchers and some of the brightest minds in the world who are dedicated to hard work. I look forward to us all working together on innovations and discoveries that will chart our path for the next century.”

David joined the Auburn faculty in 2012, and in 2018 he co-founded Nanoxort — a company that engineers novel contrast agents to equip physicians with the tools to make more accurate disease diagnoses and provide patients with more personalized, effective treatments. He has served as an assistant professor, associate professor and was recently promoted to the rank of full professor.

Prior to moving to Auburn, David served as a postdoctoral fellow and adjunct assistant professor of pharmacy at the University of Michigan. He also served as a technical manager at the Industrial Science and Technology Network and as a thermal systems engineer for Dynatherm Corp.

David earned his bachelor’s and doctoral degrees in chemical engineering from the University of Maryland in 1997 and 2004, respectively.

Media Contact: Austin Phillips, austinp@auburn.edu, 334-844-2444

Allan David

Categories: Engineering

Vice Chairman of the Joint Chiefs of Staff tours Auburn Engineering research centers

The Navy's "Old Salt" — a sobriquet reserved for its longest-serving surface warfare officer on active duty — just got a taste of new research.

Adm. Christopher W. Grady, who as vice chairman of the Joint Chiefs of Staff is the nation's second highest-ranking military officer, toured prominent Auburn University engineering research centers in advance of his Friday address at Auburn's NROTC commissioning ceremony, at which he will serve as commissioning officer.

"It's an immense honor to have Adm. Grady take the time to get an up-close look at the next-level research happening in the Samuel Ginn College of Engineering," said Mario Eden, dean of engineering. "We take great pride in our leading role in supporting the military's mission through our advanced manufacturing and cybersecurity capabilities."

Grady began his visit by meeting with Auburn University President Christopher B. Roberts to discuss Auburn's collaboration with the Department of Defense, as well as the university's multiple space industry partnerships, including the Auburn University Research and Innovation Campus' new status as a base of technical support operations for the Space Development Agency in Huntsville.

Grady later visited Auburn's National Center for Additive Manufacturing Excellence (NCAME), whose internationally renowned expertise in additive manufacturing characterization will feature heavily in a new $50 million advanced manufacturing project — the single largest prime research contract ever awarded to Auburn University — designed to boost the U.S. Army Combat Capabilities Development Command Aviation & Missile Center's growing modernization efforts. NCAME's integral work on NASA's Rapid Analysis and Manufacturing Propulsion Technology project, or RAMPT, is crucial to improving the performance of the liquid rocket engines that will return the U.S. to the moon — and beyond.

Other stops included the new Design and Innovation Center in the Brown-Kopel Engineering Student Achievement Center, the most hands-on campus makerspace in the country; the Auburn Cyber Research Center, which integrates cutting-edge engineering technology with research to develop innovative methods of protecting U.S. cybersecurity; the Auburn University Small Satellite Program, a space science and technology research and workforce development program; and the Interdisciplinary Center for Advanced Manufacturing Systems, whose millions in Department of Defense contracts go toward the increasingly critical mission of reducing barriers inhibiting the introduction of Industry 4.0 technologies in small and medium manufacturing operations.

Grady liked what he saw.

"Auburn University is a premier research institution with some of the best facilities in the country," Grady said. "The cutting-edge work, especially in advanced manufacturing and cybersecurity, is vital for U.S. national security and our presence in space."

Media Contact: Jeremy Henderson, jdh0123@auburn.edu, 334-844-3591

Pictured from the left: Lt. Gen. Ronald L. Burgess, Christopher B. Roberts, Adm. Christopher W. Grady and Steven Taylor

Categories: Engineering, Security

Aerospace engineering faculty earn DOD research funding to study rotor performance in adverse environments

Nek Sharan, assistant professor in the Department of Aerospace Engineering, and Vrishank Raghav, associate professor of aerospace engineering are one of the 27 collaborative academic teams awarded research projects through the U.S. Department of Defense's Defense Established Program to Stimulate Competitive Research (DEPSCoR) program.

According to the DOD, DEPSCoR is a capacity-building program designed to strengthen the basic research infrastructure at higher education institutions in underutilized states and territories.

Sharan is the principal investigator for the project 'Dynamic Loads and Flow Structures on a Hovering Rotor Blade Above Inclined Ground.' Raghav, the co-PI, is collaborating with Sharan to investigate the impact of airflow on rotor blades while hovering over inclined surfaces.

“Rotorcraft, including military helicopters and modern drones, often operate in these conditions, but the amount of thrust produced and why they reduce or increase in such unique scenarios aren’t well understood,” Sharan said.

Sharan plans to develop advanced simulations to model the complex airflow around the rotor blades and understand how thrust is affected. Additionally, they plan to investigate the influence of different airflow patterns on ground forces.

Raghav’s responsibility involves conducting experiments to measure aerodynamic forces and airflow around the blades utilizing his novel Rotating Three-Dimensional Velocimetry (R3DV) methodology. This method facilitates the measurement of time-resolved 3D velocity fields within the rotating frame of reference.

"The measurements needed for understanding this problem are very challenging and our technique — R3DV — is one of the few that is capable of quantifying this flow field,” Raghav said.

Sharan will use the data gathered by Raghav to validate his code/solver.

“Once my solver is validated and we can expect accurate results, it may be scaled to simulate flow conditions experienced by the rotorcraft (helicopters or drones) at realistic scales,” Sharan said.

Sharan understands that the simulations need to be performed over a range of parameters, by varying the types of slopes, rotor height and the number of blades. This will allow him to explore how these factors influence the flow field, ground forces and the thrust experienced by the rotorcraft.

When helicopter blades hover over dusty areas, they can create a phenomenon known as a “brownout,” which significantly impairs the pilot’s visibility. Similarly, rotorcraft operating near snow-covered mountains may encounter a “whiteout” effect. These conditions pose severe safety concerns for personnel and equipment on the ground and aboard the vehicle.

“An incomplete understanding of the ground effects has led to several rotorcraft accidents in recent times, so there is considerable interest in understanding both the thrust dynamics and the overall flow field,” Sharan said.

If pilots know how fast to descend to a lower altitude and how high above the ground to hover, it will reduce risks for personnel or passengers exiting the vehicle or dropping supplies/equipment to the ground. Additionally, it could reduce the generation of dust or other environmental disturbances.

The DEPSCoR Research Collaboration competition is open to tenured and tenure-track faculty members in 37 states and territories eligible for DEPSCoR funds. The competition helps introduce potential researchers to DOD's unique research needs and supporting research ecosystem. Each collaborative team pairs a PI new to the DOD research enterprise with a mentor who has previously worked with the department.

Raghav recently secured a DOD grant for his research on implementing the R3DV technique in forward flight conditions. He said that Sharan's work complements his own because they both combine computational and experimental methods. Since Raghav's research tackles similar challenges outlined by the DOD, their collaboration makes sense.

“I was very grateful to have the opportunity to help a colleague through this process,” Raghav said. “It provided me an opportunity to share what I have learned over the past few years and I am happy that it helped Nek win the DOD grant.”

Media Contact: Dustin Duncan, dzd0065@auburn.edu, 334-844-2326

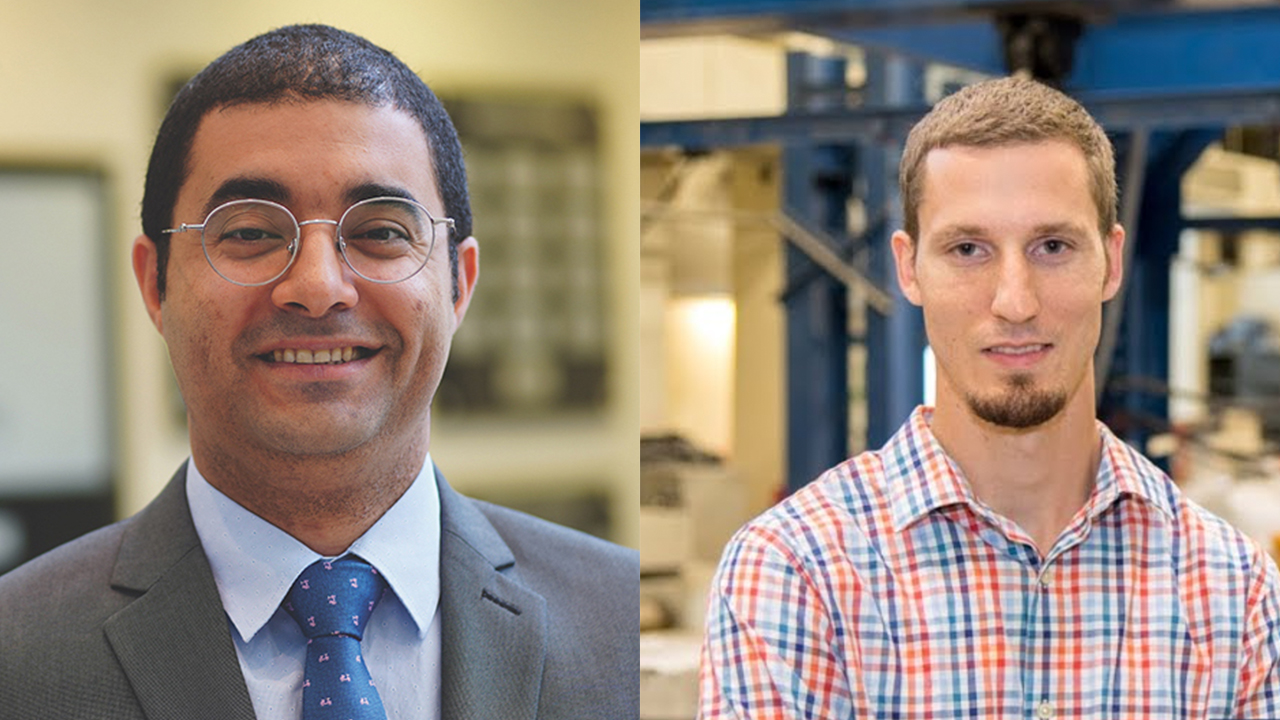

Nek Sharan (left) and Vrishank Raghav (right), both aerospace engineering faculty members, will investigate the impact of airflow on the rotor blades of helicopters and drones hovering over inclined surfaces.

Categories: Engineering, Security

Space Development Agency partners with Auburn University Research and Innovation Campus for logistical support

Auburn University is making space for the Space Development Agency (SDA).

Located just outside Redstone Arsenal in Huntsville, the new Auburn University Research and Innovation Campus (AURIC) is set to become a base of technical support operations for the SDA, the sole arm of the United States Space Force operating in the state of Alabama.

In addition to logistical support, the partnership will provide opportunities for collaboration between the SDA and the Auburn University Applied Research Institute located within AURIC.

"This new phase of Auburn's relationship with the SDA is especially rewarding because it perfectly aligns with the original vision for the Auburn University Research and Innovation Campus," said Steve Taylor, senior vice president for research and economic development. "We designed this cutting-edge campus not only to facilitate research but to be the go-to destination for government and industry entities within Redstone looking to accommodate and even train their workforce."

Taylor is especially pleased that the first outside entity to raise its flag over AURIC is space focused.