Food Systems News

Hatchery scientists take on project to help U.S. largemouth bass producers

In the $1.5 billion U. S. aquaculture industry, largemouth bass production is a small fry.

The fish’s unusually high mortality rate across all stages of production makes it a challenge for farmers to raise this fish for profit. Researchers at Auburn University hope to expand production of largemouth bass in Alabama and the U.S. by solving the problem of high mortality rates.

A team of hatchery scientists from the Alabama Agricultural Experiment Station’s E. W. Shell Fisheries Center was awarded $650,000 by the National Institute of Food and Agriculture to study the critical larval stage of largemouth bass development and share their findings with producers nationwide.

“The larval stage is the hardest stage of fish production,” said Ian Butts, associate professor and the grant project’s director. “They die so easily.”

Largemouth bass is the most popular sportfish in America, and its market value far surpasses other aquaculture species, like trout and catfish. However, due to the difficulty in raising the fish, fewer than 200 of the nearly 3,000 fish farms in the U.S. produce largemouth bass, according to the USDA’s most recent Census of Aquaculture.

Meanwhile, competitors, such as China, have increased their production of largemouth bass in recent years. America has become dependent on these other countries to supply seafood products, importing nearly 90% of the fish it consumes.

Further, as few farms raise largemouth bass from larval to juvenile stages, the U.S. suffers a serious bottleneck in production. This means not only fewer bass for sale at market as a food source, but also fewer for restocking lakes for anglers.

The problem behind the often 80% mortality rate in fish production, according to Butts, lies in the traditional method of farming largemouth bass.

Farmers tend to rely on adult bass broodstock to spawn in a commercial hatchery setting. The larvae are transferred to grow-out ponds where they feed on plankton. When large enough, they are caught and returned to the hatchery facility to be trained to feed on a commercial diet. Finally, they’re transferred back to a pond to grow until harvest.

The stress of this back-and-forth movement, in addition to the introduction of disease, the impact of natural predators (especially fish-eating birds) and environmental factors, like low oxygen levels in ponds, lead to high mortality rates.

“Farmers want to be able to have them indoors the whole time to streamline their production and keep them in a more controlled environment,” Butts said.

The series of experiments designed by Butts and his colleagues will yield best practices for largemouth bass producers nationwide to help increase fish production.

For example, experiments to study the impact of stocking density on production will help to determine the ideal ratio of larval bass to planktonic prey. Too few prey and the bass could starve, while too many creates a “confusion effect” where bass become overwhelmed, never attack prey and starve.

“It’s like it’s raining Big Macs, and you don’t know which one to grab,”Butts explained.

Bass are visual predators. Light intensity and the color of the tanks can affect their ability to see prey. Experiments will determine the optimal light intensity and tank color to ensure that more fish make it through the early stages of development.

Other experiments will determine if certain foods, given early in life, predispose bass to a soybean-based commercial diet later in life. Live food is expensive for farmers. The sooner farmers can switch to commercial fish food, the more profitable and sustainable production will become.

The research team is made of Ian Butts, Timothy Bruce, Anita Kelly, Luke Roy and Allen Davis, all from the School of Fisheries, Aquaculture and Aquatic Sciences at Auburn. Karolina Kwasek of the University of New Hampshire is also a member of the grant team.

The grant funding will allow the research team to offer full assistantships to a PhD student and three new master’s students who will join the School of Fisheries, Aquaculture & Aquatics Sciences in the College of Agriculture. These students will carry out many of the experiments under the direction of the research team.

“These fish are fed every two hours from 6 a.m. to midnight every day,” Butts said. “A team is necessary.”

The experiments will be carried out over a four-year period, predominantly at the E. W. Shell Fisheries Center in Auburn, which has more than 200 ponds on 1,600 acres of research land.

“Not too many places in the country have hundreds of ponds, a fisheries center and all the right lab equipment … right in the heart of largemouth bass fishing,” Butts said. “You can’t usually get that in one facility.”

Categories: Food Systems, Agriculture

Auburn project part of $16.2 million innovative plant breeding effort

An Auburn University researcher’s project is part of a $16.2 million U.S. Department of Agriculture National Institute of Food and Agriculture (USDA-NIFA) effort to address breeding crops for the future.

The Plant Breeding for Agricultural Production program area priority in the Agriculture and Food Research Initiative provides funding for fundamental, innovative breeding research across a wide variety of agronomic crops, specialty crops, wild relatives and timber species relevant to U.S. agriculture. The Auburn project is one of 32 nationwide.

Marnin Wolfe, a researcher in the Alabama Agricultural Experiment Station and assistant professor in quantitative genetics in the College of Agriculture’s Crop, Soil, and Environmental Sciences Department, is leading a $300,000 project entitled “Leveraging genomic and phenomic selection to breed better cover crop and forage mixtures, faster.”

The Wolfe Lab uses genetics, genomics and breeding to generate sustainable solutions to crop production challenges. It is focused on harnessing the benefits of cover crops to build sustainable agriculture systems.

“Cover cropping is the increasingly common practice of planting a crop between cash cropping seasons to protect and improve soil health,” Wolfe said. “The species used as cover crops also serve another critical purpose: forage production. Forages are crops planted to feed livestock, and livestock are a multi-billion dollar industry in the U.S.”

The Wolfe Lab will implement novel applications of genomic and phenomic prediction in intercrop breeding trials.

“Our specific focus is on developing a dual-purpose forage and cover crop mixture of crimson clover (Trifolium incarnatum) and oats (Avena sativa) with enhanced intercrop-ability and overall performance,” Wolfe said. “Beyond clover and oat mixtures, the strategy we are piloting holds the potential to accelerate the development of better mixtures in many additional intercropping systems.”

Breeding for intercrops is a massive combinatorial problem, which has limited the development of intercrop-adapted cultivars, he explained.

“Typically, multiple crop species are grown together because they improve biomass,” Wolfe said. “The best combination of varieties is crucial for optimal outcomes. While existing research has primarily focused on agronomic management of species mixtures, they have relied on cultivars developed under monocrop conditions. It is clear that intercrop conditions create a distinct environment and thus, dedicated breeding efforts are needed to unlock their full potential.”

Wolfe’s lab is addressing these long-standing challenges with genomic prediction, which is a technique for using DNA sequence information to forecast the potential outcomes of inheriting different combinations of genes.

Genomic prediction has revolutionized the field of genetics, speeding up the results of plant and animal breeding. It is also used to assess the risk for inheriting genetic diseases in humans.

“We are going to grow out a large collection of clover varieties and test them in combinations with many different oats,” he said. “We’ll use drones to monitor growth and development of our clover-oat mixtures. In parallel, we will collect DNA from all of our clovers and our oats.

“We will develop models to predict the performance of previously untested combinations, based only on genomic information. Because we cannot test all combinations practically, our goal is to be able to predict which clover-oat combinations are most promising so we can focus on testing those in the field.”

Collaborators on the project include Alvaro Sans-Saez, assistant professor in the Department of Crop, Soil & Environmental Sciences; Yin Bao, assistant professor in the Department of Biosystems Engineering; and Esteban Rios, assistant professor in forage breeding and genetics at the University of Florida.

Marnin Wolfe

Categories: Food Systems, Agriculture

Auburn University study reveals honey bee nest structure is surprisingly adaptive, resilient

Researchers from the Department of Biological Sciences at Auburn University have discovered that honey bee colonies have surprising abilities to adapt and maintain their nest structure, even in the face of severe disruptions.

Contrary to previous assumptions, the researchers found that the disruption of three-dimensional nest structure while colonies were building their nests did not hinder colony performance. The findings shed new light on the adaptive nature of honey bee colonies and how nest structure contributes to colony function.

The study focused on the intricate three-dimensional nest building behavior of honey bee colonies. To investigate the development of honey bee nests over time, the research team employed non-destructive, photo-based sampling methods using moveable wooden bee-frames. This approach allowed them to observe and analyze the growth and organization of combs within the nests without sacrificing the colonies. They found that honey bees rapidly build a well-connected spheroid nest composed of parallel combs that expand in all directions from the nest origin.

To test how important this stereotyped structure is for colony development, the international team of researchers disrupted the nest structure of another group of colonies by rearranging the movable wooden bee-frames in a new randomized order every week. They initially hypothesized that this disruption would negatively impact colony-level performance. However, the study revealed no significant difference in worker population, comb area, hive weight, or nest temperature between colonies with intact nest structures and those with disrupted nest structures.

The surprising lack of difference in colony performance led the researchers to explore the mechanisms behind the honey bees’ ability to compensate for repeated disruptions. By modeling the colony’s building behavior, they found that colonies prioritize structural connectedness when expanding their nests, actively repairing connections in the three-dimensional nest structure following the experimental disruptions. This highlights the colony’s ability to adapt their comb shape to the available space within a cavity, an essential skill in the wild, where cavities are not uniform.

The study also identified potential reasons why honey bees prioritize nest connectedness. A well-connected nest reduces the surface area-to-volume ratio, potentially enhancing thermoregulation efficiency, improving larvae development and winter survival. It also may facilitate information-sharing among colony members and optimize travel distances within the nest for essential activities such as foraging, feeding larvae, and egg-laying.

“We were all surprised that the shuffled colonies performed as well as they did,” said Auburn’s Peter R. Marting, the first author of the study. “We expected some shuffled colonies wouldn’t even survive the summer. The bees’ resilience led us to take a closer look at how and where exactly workers were adding new comb to shape their nests and ultimately led us to develop the predictive comb growth models.”

The research team believes that understanding the underlying mechanisms behind these adaptive building strategies in social insects can provide valuable insights into collective intelligence and resilience in complex systems.

The study, “Manipulating nest architecture reveals three-dimensional building strategies and colony resilience in honeybees,” appears in the journal “Proceedings of the Royal Society B: Biological Sciences” and is available for reference.

“Honey bees are an extremely well-studied system, but many basic developmental questions remain unanswered, because we don’t typically look at the colony’s natural life cycle,” said Michael L. Smith, senior author of the study. “Sometimes you just have to do the experiment and see what the bees will do.”

Honey bees (photo by Peter R. Marting)

Categories: Food Systems, Energy & the Environment, Life Sciences, Agriculture

Auburn ranked in top 100 of U.S. research institutions for second straight year

For the second straight year, Auburn University is ranked in the top 11% of U.S. research institutions, coming in at No. 100 among 915 universities, according to the National Science Foundation’s most recent Higher Education Research and Development, or HERD, Survey.

Among public universities, Auburn is ranked No. 68 out of 412 institutions. The university also increased its research and development spending overall by $11.1 million in 2021.

“Auburn’s second year of ranking among the nation’s top 100 research institutions continues to be a significant accomplishment,” said James Weyhenmeyer, Auburn’s vice president for research and economic development. “Our researchers continue to be committed to engaging in impactful research—much of which is critical to supporting major Alabama industries—and that commitment is reflected in Auburn’s being highly ranked once again.”

The annual survey, compiled from fiscal year 2021 research expenditures, saw Auburn hold its position in the rankings’ top 100 even as 10 other SEC schools saw their positions fall. During the five-year period from 2017-21, Auburn’s annual research expenditures increased from $190.3 million to $266.4 million, resulting in a rankings jump of 14 places.

For universities without a medical school, Auburn again ranked No. 61 nationally and No. 1 in the state. Auburn also was highly ranked nationally in a number of specific fields of research, including No. 51 in engineering (up three spots), No. 53 in mathematics and statistics (up one spot) and No. 94 in physical sciences, all state bests. Auburn also ranked No. 41 for non-science and engineering research expenditures (up two spots). These fields include business administration, management, communications, education, humanities, social work and human sciences.

A hallmark of Auburn’s research is the diversity of its funded projects. Highlights include:

-

The U.S. Department of Agriculture recently awarded Auburn’s College of Forestry, Wildlife and Environment $2.1 million for studies into mitigating needle blight, a growing threat to pine trees. According to EDPA, the forest products industry is the state’s largest manufacturing industry. A second USDA award of more than $1.5 million is funding another study in the college aimed at reducing the effects of climate change through forest carbon sequestration.

-

The Auburn College of Agriculture’s Department of Poultry Science was awarded more than $1.2 million for research into sustainable poultry processing, as well as received additional funding of approximately $1.3 million for a study of the effects of environmental conditions in production efficiency and product quality in commercial poultry operations. Like forestry, poultry production is another major industry in Alabama. Alabama ranks fourth in the nation in broiler (chicken) production.

In addition to the high ranking in the NSF HERD Survey, Auburn is recognized by the Carnegie Classification of Institutions of Higher Education as a top-level, or R1, university with “very high research activity.”

Categories: Food Systems, Science, Technology, Engineering and Mathematics (STEM), Engineering, Auburn In the News, Education, Agriculture, Liberal Arts

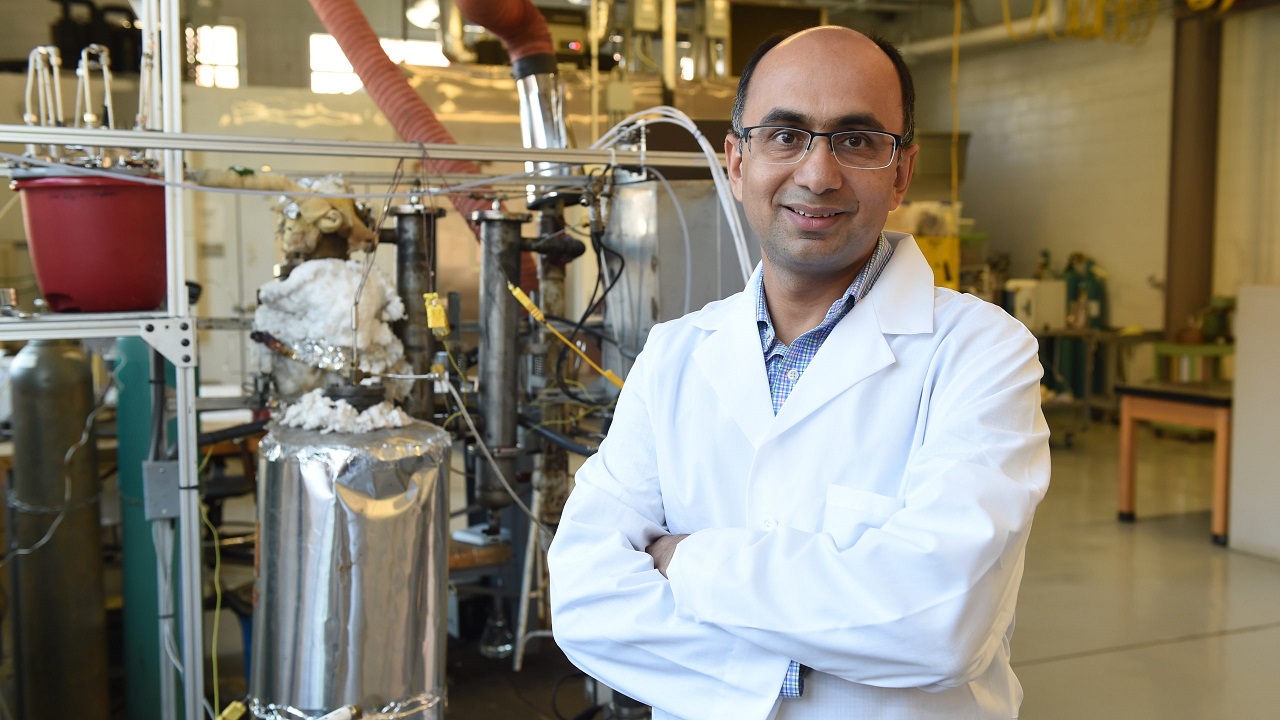

Auburn researchers lead $2 million research project to produce hydrogen

Auburn University researchers are leading a $2 million Department of Energy grant that aims to produce hydrogen from blended feedstock such as legacy waste coal, forest residues and municipal solid waste.

“The benefits of converting waste coal, biomass and food waste are twofold,” said Sushil Adhikari, professor of biosystems engineering and principal investigator for the proposal. “First, it will help us to reduce greenhouse gas emissions from hydrogen production. Second, it will help to solve food waste problems.”

AU’s co-principal investigator for the project is Oladiran Fasina, department head and alumni professor for the College of Agriculture’s Department of Biosystems Engineering.

Other engineering staff involved in this project are James Johnson, Caroline Whiting and Bobby Bradford, who work for the Department of Biosystems Engineering and the Center for Bioenergy and Bioproducts (CBB). The CBB is funded by the Alabama Agricultural Experiment Station (AAES), College of Agriculture, and the Samuel Ginn College of Engineering.

The Biden Administration is focused on producing clean hydrogen at $1 per kg, Adhikari said, and this goal can be reached through the use of biomass and food waste while reducing greenhouse gas emissions.

The six primary objectives of the project — titled “Hydrogen Production from Modular CO2 Assisted Oxy-Blown Gasification of Waste” — are to understand how biomass, waste coal and food waste will flow into the gasifier; how biomass, coal and food waste composition will impact the gas composition and quality; and to understand the cost of hydrogen production from biomass, coal and food waste blends.

Auburn researchers are partnering with RTI International — an independent, nonprofit institute that provides research, development and technical services to government and commercial clients worldwide — to facilitate a unique combination of experimental and modeling research to produce hydrogen from the gasification of a coal-food waste-forest residues mixture while reducing greenhouse gas emissions.

The research will examine the gasification performance of coal waste from Alabama, food waste discarded from cities and towns and southern pine residues mixture in a laboratory-scale fluidized-bed gasifier to produce hydrogen. Food waste will be supplied by Burcell Technologies located in Cordele, Georgia.

Other specific objectives of the project are to 1) understand the effect of feedstock blends on flow properties and energy requirement for preprocessing; 2) examine the effect of feedstock blends on syngas composition and contaminants; 3) evaluate water-gas shift catalysts, and sulfur and metals removal sorbents for high-purity H2 production; 4) demonstrate 100 hour operation of an integrated system for waste blend gasification and syngas clean up and conditioning at a 1 kg/hour scale gasifier; 5) perform techno-economic analysis for hydrogen production using waste materials; and 6) develop a technology maturation plan to advance the proposed technology beyond TRL-4.

Flow properties for the coal-food waste-forest residues mixture will be measured, and syngas composition will be analyzed for permanent gases such carbon monoxide, carbon dioxide, methane and hydrogen along with contaminants such as tar, hydrogen sulfide and ammonia.

RTI will develop a gas cleanup system and process model for hydrogen production from the waste coal-food waste-biomass mixture using data gathered in the laboratory-scale system at Auburn University.

The 24-month research project will have applications in industries such as fertilizer synthesis, power production and chemical production, Adhikari said.

Sushil Adhikari

Categories: Food Systems, Energy & the Environment, Agriculture

Auburn University research looks to overcome barriers to aquaponics in food deserts

It looks like a natural fit: a sustainable system that produces fresh vegetables and fish located in food deserts with marginalized populations.

And, while there has been an explosion in the interest surrounding such an arrangement, there are significant technological and social barriers hindering its adoption.

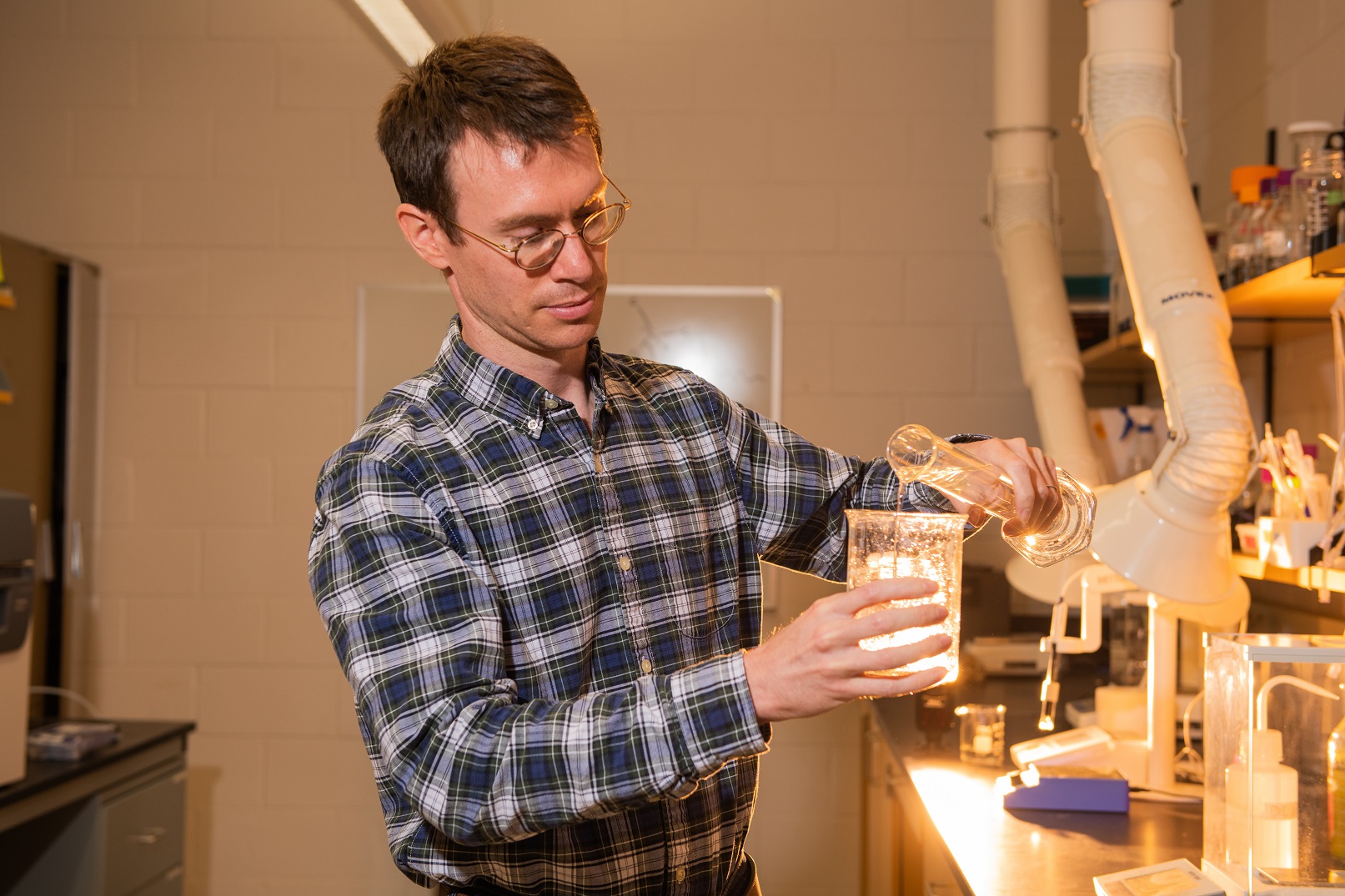

Overcoming these barriers is the goal of a research project being conducted at Auburn University and led by Brendan Higgins, assistant professor in the College of Agriculture Department of Biosystems Engineering.

“At its best, aquaponics allows local people to produce their own fresh fish and produce in a sustainable manner: The wastewater from the fish is used to provide water and fertilizer to the plants,” Higgins said. “However, the development of this fusion of aquaculture with hydroponic vegetable production in food deserts doesn’t come without barriers.”

These barriers include: 1) systems that are prone to instability without advanced technical knowledge; 2) fish and produce quality that do not meet consumer quality demands (e.g., muddy fish flavor); and 3) food safety issues, given that pathogens in the fish wastewater can contaminate the vegetables.

“A failure to address these three issues will continue to place aquaponics systems—and the corresponding nutritional and environmental benefits—out of reach for marginalized populations,” Higgins said.

The objective of the research project—which is working with a $575,730 grant from the National Science Foundation—is to improve understanding of how aquaponics design decisions (e.g., integrating algae into biofloc, coupled vs. decoupled systems) impact microbial stability, pathogen dynamics and product quality.

“Our central hypothesis is that algal biofloc and decoupled systems will exceed the performance metrics of bacteria-centric biofloc and coupled systems (85% of current systems) in terms of system stability and ease of operation, nutritional and flavor profiles, and pathogen management when placed in the hands of novice users,” Higgins said.

The project will allow researchers to rigorously test integrating algal-biofloc and decoupled plant production into small-scale aquaponics systems, both independently and in combination.

Algal biofloc, Higgins explained, is a mixture of algae and bacteria that transform nutrients into less toxic forms for both fish and plants. Bacteria biofloc does the same thing but researchers have found that the mixture of algae and bacteria is even more effective, at least in a lab setting.

“We want to know if this holds true in actual aquaponics systems,” he said.

Coupled aquaponics means there is recirculation of water between the fish tank and the plant bed (and back again). Decoupled means water flows in one direction: from fish to plants but not back again.

“Our project looks at both of these design choices, both independently and in combination,” Higgins said.

The test systems will be operated by high school students in east Alabama after hands-on training in a synergistic school-university partnership.

“Our team has extensive experience conducting research on aquaponics systems and algal-bacterial treatment of waste, and it engages frequently in educational and outreach programs with novice users,” he said.

Co-investigators on the project include David Cline, Department of Fisheries and Aquatic Sciences; Sheena Stewart, Department of Educational Foundations, Leadership, and Technology in the College of Education; and Luz de-Bashan and Paola Magallon, Bashan Institute of Science.

The three specific aims of the research project are to:

-

Test the integration of algae and decoupling into biofloc aquaponics to improve stability and ease of operation for novice users (high school students). Researchers hypothesize that the integration of green algae into the biofloc and deployment into a decoupled aquaponics system will improve system stability (nitrification capacity) and reliability (plant and fish survival).

-

Determine the contribution of algal biofloc to improved nutritional quality and the flavor profile of aquaponics products. Integrating Chlorella algae into the biofloc will hypothetically increase the omega-3 fatty acid profile of fish, antioxidant content of vegetables, and improve the fish flavor profile by displacing opportunistic bacteria and cyanobacteria species that generate muddy flavors.

-

Quantify the impacts of algal biofloc and decoupling on indicator pathogens in aquaponics. The presence of algal taxa like Chlorella in the biofloc and use of decoupled systems hypothetically will reduce the presence of indicator pathogens. While students and teachers will run the different aquaponics systems, Auburn University and the Bashan Institute of Science will conduct advanced chemical, microbiological and genomic analyses of the systems. Students will evaluate system ease-of-use and flavor of products through surveys.

The research project is significant because it is expected to resolve persistent challenges that have hindered aquaponics adoption to date, Higgins said.

“For example, the integration of algae into decoupled biofloc production has great promise to resolve microbial stability and pathogen concerns,” he said. “Moreover, our improved understanding of these microbial dynamics in aquaponics can translate broadly to other areas of aquaculture, nutrient recovery and waste management. An improved understanding of how design choices impact user experience can translate to research on other scalable food production technologies.”

The project will lead to measurable benefits by enhancing the education of high school student participants who live in low-income communities with limited food access.

“Approximately 225 students will engage in hands-on learning by operating the aquaponics systems, allowing them to learn and apply knowledge of agriculture, biology, chemistry, nutrition and engineering,” Higgins said.

“This is important because these students are the future of sustainable food production: The skills they learn extend to a wide range of career and education pathways. We expect that reaching them in their formative years will result in measurable changes in self-perceptions regarding STEM topics, which will be assessed through survey instruments.”

For media inquiries, contact Kristen Bowman at kbowman@auburn.edu.

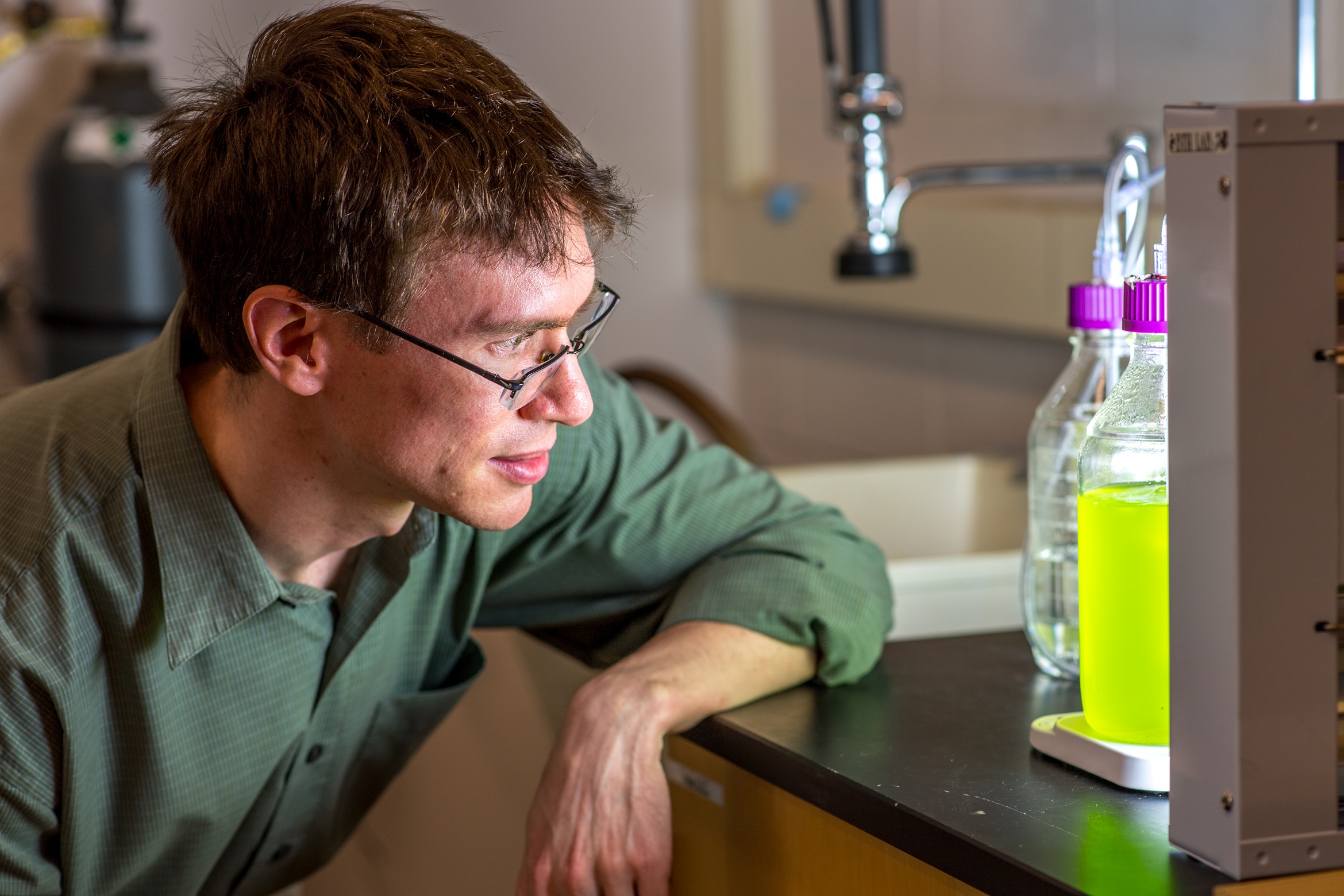

Brendan Higgins, assistant professor in Auburn University’s College of Agriculture, is leading a research project that seeks to improve understanding of how aquaponics design decisions affect microbial stability, pathogen dynamics and product quality.

Categories: Food Systems, Agriculture

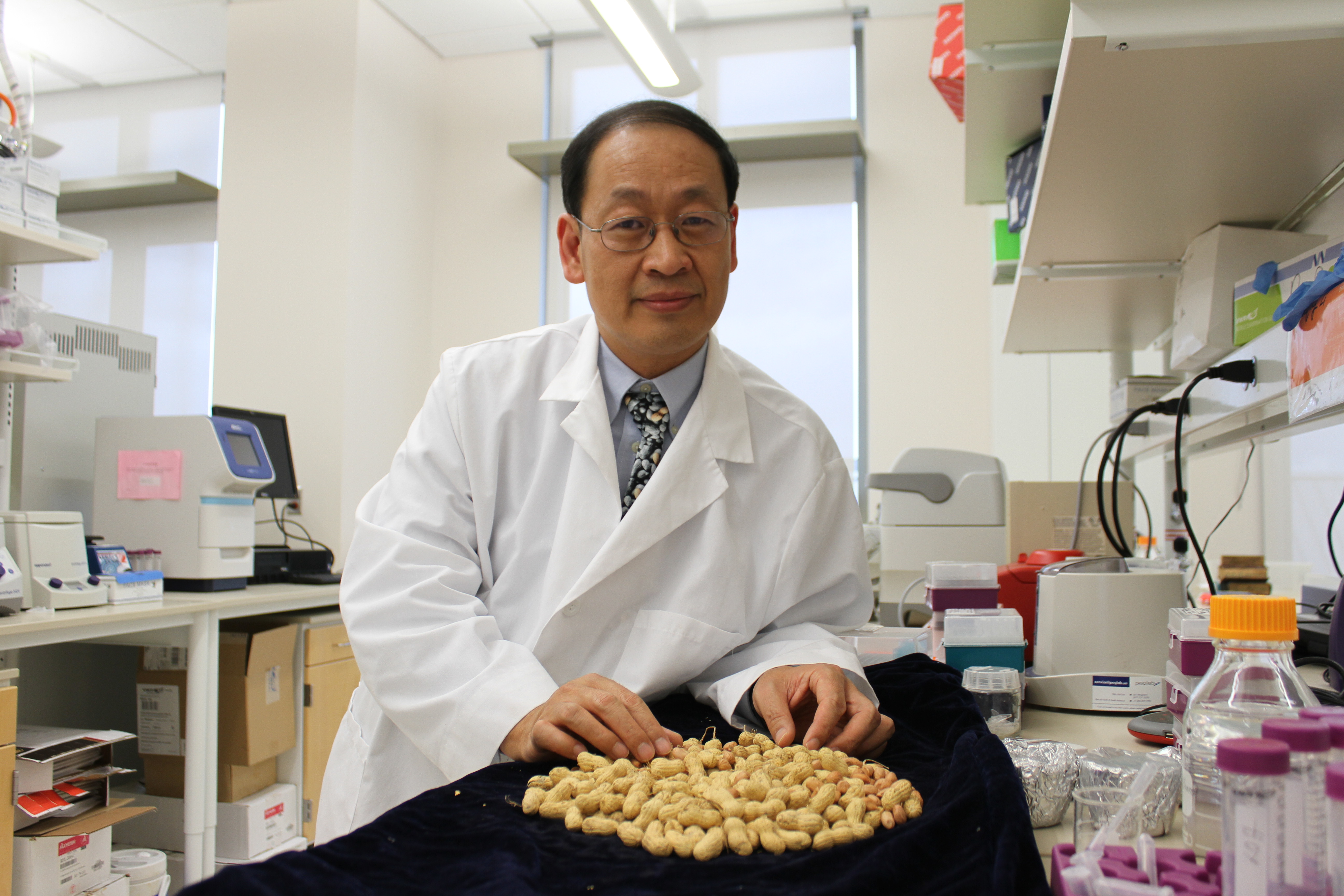

Auburn University researchers first to map blue catfish genome

An Auburn University research team from the College of Veterinary Medicine and the College of Agriculture recently became the first to map a high-quality genome assembly of the blue catfish.

The genome, which was published in the journal GigaScience, is essential for genetic improvement using gene-editing or genome-assisted selection and will aid in the genetic enhancement of better catfish breeds for the multimillion-dollar catfish farming industry.

Catfish farming is the largest aquaculture industry in the U.S., accounting for approximately 70% of the nation’s total aquaculture output. Mississippi, Alabama, Arkansas and Texas account for the great majority of total U.S. freshwater catfish production, with Alabama ranking second only behind Mississippi. The primary fish utilized for farming purposes is a hybrid produced by breeding male blue catfish with female channel catfish.

“The hybrid catfish is superior in growth and disease resistance,” according to Xu Wang, assistant professor of comparative genomics in animal health in the College of Veterinary Medicine’s Department of Pathobiology and adjunct faculty investigator with the HudsonAlpha Institute for Biotechnology, who is one of the leaders of the project.

“Faster growth means more profit. Originally, farmed fish were primarily channel catfish, but three major bacterial pathogens resulted in a 40% loss of production and annual economic damage of over $100 million in the U.S. industry alone. The hybrid mix of the blue and channel catfish has improved disease resistance and reduced mortality by half.”

Even so, Wang says there is a critical need for further genetic improvement using genomic methods.

“The channel catfish genome was mapped in 2016 by John Liu’s lab at Auburn [now at Syracuse University], but the blue catfish genome was not available until we published it,” Wang added. “Our high-quality blue catfish genome addresses the urgent needs to achieve the long-term goal of improving growth, feed utilization, stress and disease resistance and reproduction.”

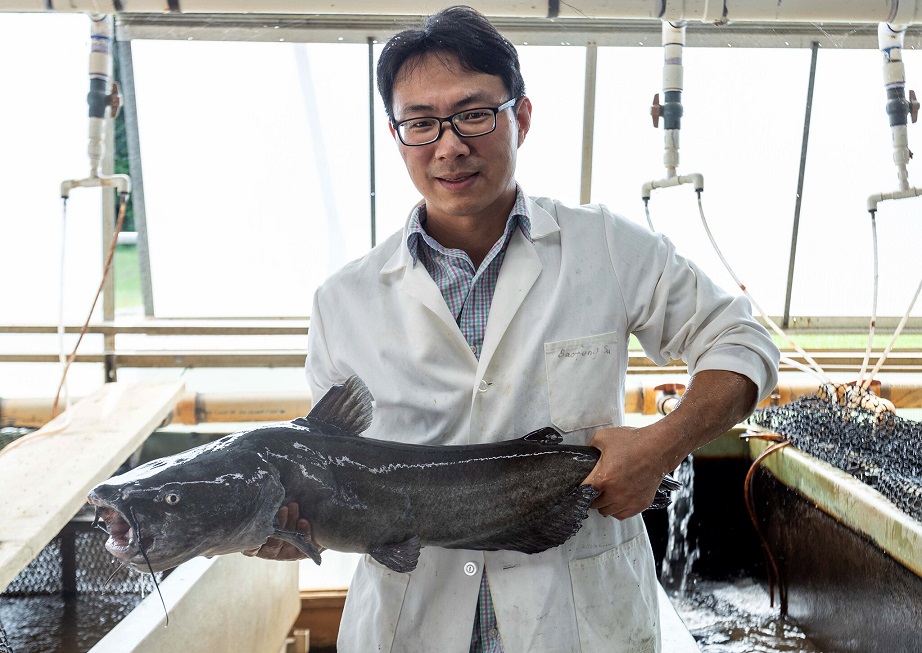

Wang served as senior author of the GigaScience paper, assisted by Haolong Wang (no relation), a doctoral student in biomedical sciences supported by both an Auburn Presidential Graduate Research Fellowship and a College of Veterinary Medicine Dean’s Fellowship. The veterinary researchers collaborated closely with a team from the College of Agriculture’s School of Fisheries, Aquaculture and Aquatic Sciences led by Professor Rex Dunham, an internationally recognized authority in the genetic enhancement and gene editing of catfish.

“This is a fantastic step forward,” Dunham said of the mapping of the blue catfish genome. “There have been many genetic enhancement projects related to gene transfer and gene editing that were not possible for blue catfish without it. As a result, we could not do parallel work with what we are doing with channel catfish. Since a hybrid between channel and blue is the best genetic type for the catfish industry, that also put limitations on what we could do with these tools to improve the hybrid.

“That roadblock is now gone. Having the blue catfish genome available opens a huge treasure chest of markers we can use for other approaches, such as marker assisted selection, and also gives us many more tools to distinguish and track different genetic types of blue catfish. Thanks to this research, we are much less limited than before.”

For media inquiries, contact Jayne Hart at kucerje@auburn.edu.

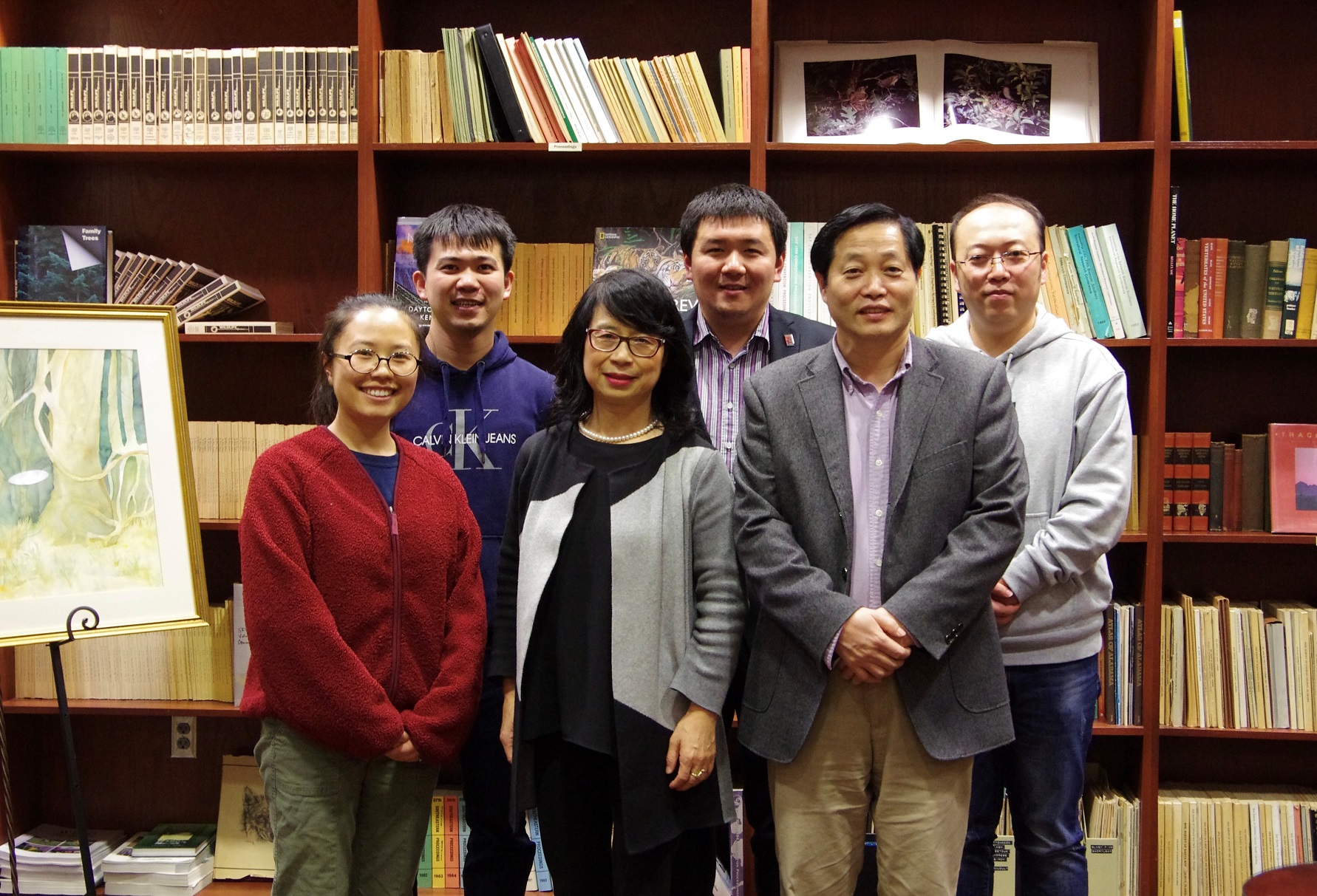

Auburn University postdoctoral student Baofeng Su is part of an Auburn research team that recently became the first to map a high-quality genome assembly of the blue catfish.

Categories: Food Systems, Agriculture

Auburn University part of $20 million statewide collaboration to boost plasma science, engineering

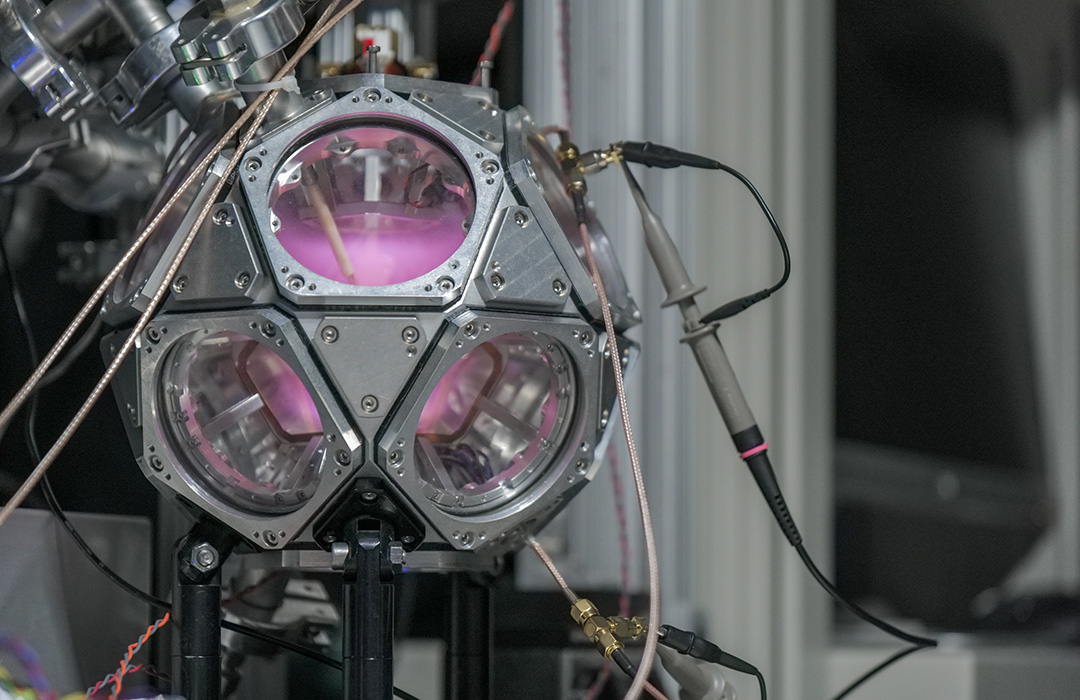

Auburn University is part of a $20 million collaboration among nine Alabama universities and one private firm to develop transformative technologies in plasma science and engineering, or PSE.

The five-year effort—which is being led by the University of Alabama in Huntsville, or UAH—is funded by a grant from the National Science Foundation, or NSF, Established Program to Stimulate Competitive Research, or EPSCoR. The goals of the Future Technologies enabled by Plasma Processes, or FTPP, initiative are to develop new technologies using plasma—the most abundant form of matter in the observable universe—in hard and soft biomaterials, food safety and sterilization and space weather prediction.

“This research directly impacts two of the largest industries in the state of Alabama, space and agriculture,” said Ed Thomas Jr., interim dean, Auburn College of Sciences and Mathematics and project lead. “For more than three decades, Auburn has been a leader in plasma research, and we have one of the highest ratios of plasma physicists in our faculty in the entire nation.”

Auburn’s team includes: Saikat Chakraborty Thakur, Uwe Konopka, Evdokiya (Eva) Kostadinova, Yu Lin, Stuart Loch, David Maurer, Joseph Perez from the Department of Physics, Mary Lou Ewald, director of COSAM Outreach, Virginia Davis from the Department of Chemical Engineering and Amit Morey from the Department of Poultry Science.

“The Alabama EPSCoR program continues to promote cutting-edge research and economic advancement in the state, and this funding presents a great opportunity for Auburn University and its collaborators,” said James Weyhenmeyer, Auburn’s vice president for research and economic development.

The alliance will build Alabama’s PSE research capacity, as well as the supporting workforce, while making the state a world-renowned PSE hub.

“The funding is the result of a team effort from the co-investigators in assembling the group, who generated the concepts and ideas underlying the proposal and executed the plan by writing a successful proposal,” said Gary Zank, FTPP’s principal investigator and director of UAH’s Center for Space Plasma and Aeronomic Research, or CSPAR, and the Aerojet Rocketdyne chair of the Department of Space Science.

“The Alabama EPSCoR committee that oversees all the Alabama EPSCoR activities—especially Professor Chris Lawson and his team of Alabama university vice presidents of research—was instrumental in guiding and helping us develop the proposal.”

Alabama Sens. Richard Shelby and Tommy Tuberville, as well as former Sen. Doug Jones, have helped champion the collaboration.

“This grant will allow for ground-breaking plasma research to occur, accelerating new technologies for a variety of applications, and will further solidify Alabama as a leader in this field,” Shelby said. “I look forward to seeing the impact that this five-year initiative will have on the future utility of plasma science and engineering.”

Tuberville called the grant welcome news and said it is well-deserved for this innovative collaboration.

“Our state is home to many talented researchers and developers, and this funding will go a long way in making Alabama a leading pioneer in PSE research and stimulating meaningful advancements in plasma technologies,” Tuberville said.

Although different in intentions, research goals and scope from a previous $20 million NSF EPSCoR grant awarded in 2017, the new FTPP grant will continue to build plasma expertise, research and industrial capacity, as well as a highly trained and capable plasma science and engineering workforce, across Alabama.

Both plans prioritize advanced manufacturing, agricultural and food products, biosciences and biotechnology, chemical and petrochemical, energy, forestry products, information technology and cybersecurity, metal and advanced materials, nanotechnology, plasma science and transportation.

Partnered with Auburn and UAH are: the University of Alabama; (lead: R. Branam); the University of Alabama at Birmingham (lead: Y. Vohra); Tuskegee University (lead: V. Rangari); the University of South Alabama (lead: E. Spencer); Alabama A&M University (lead: R. Mentreddy); Alabama State University (lead: K. Vig); and Oakwood University (lead: A. Volkov); along with a commercial/industrial partner CFD Research Corporation (lead: V. Kolobov), that specializes in computational fluid dynamics software and is located in Cummings Research Park in Huntsville.

In addition, FTPP cooperatively partners with three national laboratories: Los Alamos National Lab, Sandia National Lab and Princeton Plasma Physics Lab. FTPP will harness and share cooperatively the project team’s collective expertise, resources and workforce.

FTTP will exploit low-temperature plasma, or LTP, physics to develop technologies for advanced materials, agriculture, food safety and health-related applications. It will use space plasma physics from the sun to the ionosphere to develop actionable space weather forecasting and nowcasting models to mitigate potentially damaging effects on spacecraft, humans and infrastructure.

Those are two of the six Grand Challenge problems identified in the Plasma 2020 decadal report. The National Academy of Sciences named Zank co-chair to produce that report in 2018, and Thomas was a member of the Plasma 2020 committee and one of the co-authors of that report.

“The FTPP project is the next step in Alabama’s and Auburn’s growing contributions in plasma science and engineering,” Thomas said. “We will use the FTPP project to continue to expand our collaborations in the state, nationally and internationally and create new educational, economic and scientific opportunities for our students and the people of Alabama.”

Proposed educational and outreach programs for college and K-12 students, collaboration with national and international partners, scientific exchange programs, workshops and internships between academic institutions and national labs and industry partners also will build PSE capacity. FTPP partnerships will work toward building a sustainable foundation from which further PSE ambitions can be realized, such as a hub for cutting edge PSE in Alabama.

The National Science Foundation Established Program to Stimulate Competitive Research, or EPSCoR, is committing $20 million to a research collaboration among nine Alabama universities and one private firm to develop transformative technologies in plasma science and engineering.

Categories: Food Systems, Energy & the Environment, Agriculture

Auburn College of Agriculture faculty member receives NSF CAREER Award to study flash drought

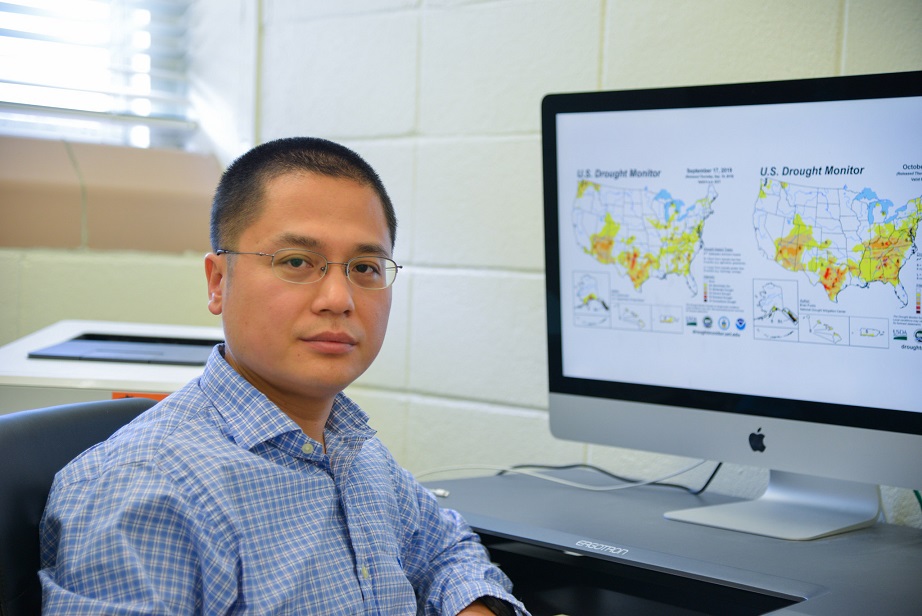

Di Tian, an assistant professor in the Auburn University College of Agriculture’s Department of Crop, Soil and Environmental Sciences, has been named a recipient of the National Science Foundation’s Faculty Early Career Development, or CAREER, Award.

The CAREER program is a foundation-wide activity that offers the NSF’s most prestigious awards in support of early-career faculty who have the potential to serve as academic role models in research and education and to lead advances in the mission of their department or organization. Activities pursued by early-career faculty should build a firm foundation for a lifetime of leadership in integrating education and research.

Tian’s award is for his integrated project titled “Analytical methods for understanding and predicting agricultural flash droughts in a changing climate.” The total award is $574,706 over five years, co-funded by the NSF Hydrologic Sciences and NSF Climate and Large-Scale Dynamics programs.

The research, Tian said, will investigate underlying drivers of agricultural flash droughts using machine learning-based causal inference analysis, develop and evaluate sub-seasonal agricultural flash drought forecasts using deep learning approaches and assess changes in agricultural flash drought under contemporary and future climate based on coupled general circulation models large ensembles.

“These research objectives will be integrated with an education and outreach plan focusing on developing and implementing innovative lessons on drought through the 4-H ‘head, heart, hands and health’ program, conducting workshops on sub-seasonal forecasts and decision making with stakeholders through a climate learning network and mentoring undergraduate and graduate students,” Tian said.

Deliverables from this project will contribute to an improved understanding and predictions of flash droughts at the regional scale and will provide a framework for analyzing a broader class of extreme climate events, which will be transferrable to different locations around the world, he added.

Flash drought, Tian said, is an extreme hydro-climate event characterized by sudden onset, rapid intensification and devastating impact on communities. A notable example is the U.S. Southeast flash drought in September 2019.

“It rapidly depletes soil moisture, posing significant water and heat stresses for agriculture and ecosystems and potentially driving water demand and irrigation expansions to traditionally rainfed regions,” he said. “Flash drought is challenging to predict because of its fast onset and development and complex land-ocean-atmosphere factors that contribute to or affect their formation. The NSF CAREER Award allows me to probe into the immediate goal to understand and predict flash droughts, which can potentially accelerate strategies for climate change adaptation.

“It also encourages me to continuously pursue my long-term research goal to integrate terrestrial hydrology, climatology and data science to address gaps and needs for better understanding and predicting hydro-climate impacts and risks in water and food sustainability, and my educational goal to integrate research and real-world applications to enhance learning and climate-aware decision making.”

Tian’s lab, Climate Analytics Group, focuses on understanding and predicting primary climate and hydrologic indicators, extreme events and impacts on water resources, ecosystem and food and agriculture using data science and artificial intelligence techniques, process-based modeling, high-performance computing and emerging earth system data generated from numerical simulations, sensors and satellites.

BY PAUL HOLLIS

Di Tian

Categories: Food Systems, Energy & the Environment, Agriculture

Auburn showcases variety of university-developed technologies at BIO Alabama conference

Auburn University recently participated in the BIO Alabama conference at the Grand Bohemian Hotel in Mountain Brook, showcasing seven of its biotechnology research developments.

BIO Alabama is the trade organization for the state’s biosciences industry. This year’s event—the first meeting following a six-year hiatus due in part to the COVID-19 pandemic—featured approximately 200 scientists and their research developments April 25-26.

Melinda Richter, global head of Innovation at Johnson & Johnson, served as keynote speaker under this year’s theme, “Building Alabama’s Biohorizons,” focusing on the future of the industry’s participation in Alabama’s innovation economy.

Auburn’s presentations included:

-

Vivosphere cell encapsulation technology platform for drug development and discovery (Elizabeth Lipke; presented by co-inventor Yuan Tian) – This is a 3D cell encapsulation method and device for more accurate and cost-effective drug screening, bioinks and regenerative medicine.

-

Anti-cancer immunotherapy targeting CD47 (James Gillespie, joint project with VCOM) – Development of an anticancer treatment that could replace immunomodulatory therapies targeting CD47.

-

Computational tool for speeding discovery of natural beneficial compounds (Angela Calderon and Cheryl Seals; presented by Kabre Heck and Muhammad Gulfam) – A collaborative project about an automated method to analyze mass spectrometry data to identify potential bioactive compounds in complex mixtures.

-

Engineered bacteria for producing biofuels and other compounds (Yi Wang) – Engineering of bacteria to express record levels of butanol for biofuel or other industrial applications or to express record levels of butyl acetate for use in foods, consumer goods or industrial processes.

-

Computationally designed compounds for treating Alzheimer’s disease (Raj Amin; presented by Ian Steinke and Fajar Wibowo) – A custom-designed therapeutic compound for treating Alzheimer’s without the side effects seen with other drugs in this class.

-

Gene therapy vectors for therapeutic treatment of neurological disease (Doug Martin) – Engineered AAV vectors for treating neurological diseases such as rabies.

-

Medical device for improving diagnosis and monitoring of neuropathy in diabetic patients (Michael Zabala and Thomas Burch; presented by co-inventor Kenny Brock, VCOM) – A medical device for accurately monitoring and measuring loss of feeling in diabetic patients. (Jon Commander is also a co-inventor and is with VCOM.)

BIO Alabama is the leading advocate for Alabama's bioeconomy. The organization represents the state on a national and international stage, promoting the intellectual and innovative capital to make Alabama a premier place to invest, start and grow in bioscience.

Alabama’s bioscience industry provides a $7.3 billion impact on the state’s economy, according to BIO Alabama data. Auburn has participated in BIO Alabama events for a number of years.

"As presenting sponsor for this year’s BIO Alabama conference, Auburn University had an important opportunity to showcase some of our latest technologies during a reverse-pitch session to industry,” said Bill Dean, executive director of the Auburn Research and Technology Foundation.

“Auburn’s participation in events like the BIO Alabama conference speaks to our role in growing the region’s bioeconomy and demonstrates our commitment to the bio-sector in the form of industry collaboration and partnerships that will advance research and impact quality of life throughout the state.”

BY MITCH EMMONS

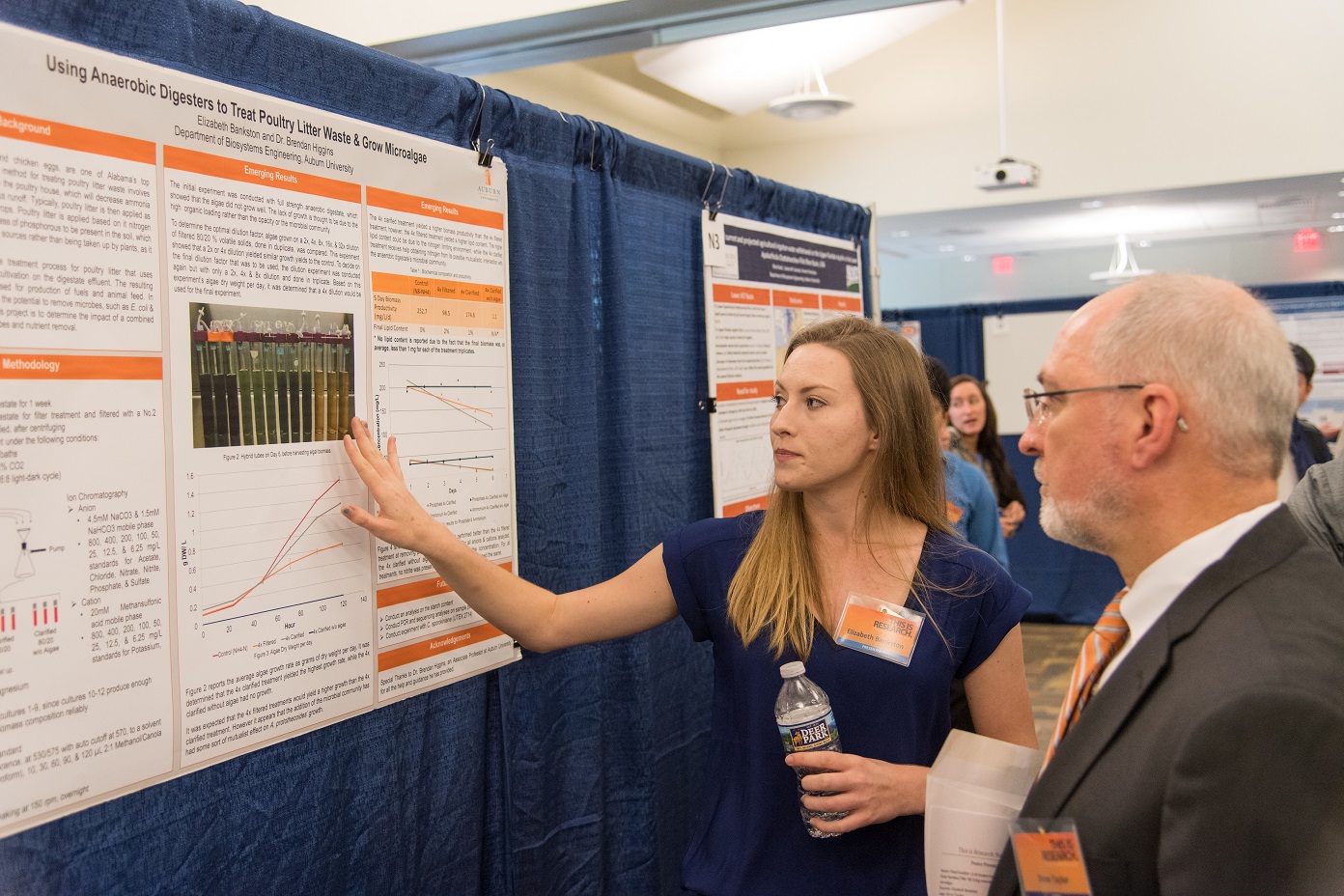

Liz Smith, College of Agriculture academic advisor, works at Auburn’s booth during the BIO Alabama conference. She talked with companies about opportunities for applied biotechnology graduates.

Categories: Food Systems, Energy & the Environment, Health Sciences, Engineering, Life Sciences, Manufacturing, Agriculture

Auburn University’s ‘AI-driven Innovations in Agriculture’ conference to feature some of Southeast’s top agricultural experts

The Auburn University College of Agriculture and its fellow land-grant universities throughout the Southeast are jointly hosting a conference next month to address the potential of artificial intelligence, robotics and automation in agriculture.

Titled “Envisioning 2050 in the Southeast: AI-driven Innovations in Agriculture,” the conference will be held March 9-11 at The Hotel at Auburn University and Dixon Conference Center thanks to funding from the USDA National Institute of Food and Agriculture.

“The Envisioning 2050 in the Southeast: AI-Driven Innovations in Agriculture conference will bring together academics, industry and stakeholders to share their expertise and develop a vision for the future,” said Arthur Appel, interim associate dean of research for the College of Agriculture. “Conference speakers include AI leaders from IBM, NIVIDIA and John Deere, as well as academics from across the country. Attendees will be able to learn about the depth and breadth of AI in agriculture from the experts who are making the promise of AI a reality.”

The caliber of speakers scheduled to attend is one of the highlights of this conference, according to co-organizer Brenda Ortiz, professor and Alabama Extension specialist in the Department of Crop, Soil and Environmental Sciences at Auburn.

Speakers include Hendrik Hamann, a Distinguished Research Staff Member and Chief Scientist for the Future of Climate in IBM Research; Mark Chaney, engineering manager of the automation delivery teams at Intelligent Solutions Group at John Deere; Steven Thomson, a national program leader with the USDA National Institute Food and Agriculture; and dozens more.

Auburn President-elect Christopher Roberts, currently dean of the Samuel Ginn College of Engineering, will give the opening remarks.

Ortiz said the invited speakers from academia, the federal government and the industry will share their work in areas such as crop production, plant and animal breeding, climate, agricultural extension, pedagogy, food processing and supply chain, livestock management and more.

“This conference is multipurpose,” Ortiz said. “The primary purpose is to share knowledge, expertise and resources among Southeastern universities, stakeholders and industries on artificial intelligence-driven innovations that can be applied to agriculture.”

This two-and-a-half-day conference will include a combination of invited plenary presentations, two-panel sessions and breakout sessions that include invited oral presentations, facilitated working sessions, a poster session and a pre-conference workshop on current and advanced AI-driven data analysis.

Kati Migliaccio, co-organizer of the conference and professor and chair of the Department of Agricultural and Biological Engineering at the University of Florida, said the timing of the conference is perfect.

“This is an opportune time to host this conference focusing on AI in agriculture in the Southeast because of the resources invested in AI, the state of innovation of AI in agriculture and the critical need to adapt agriculture for current world challenges, including labor, nutrition, energy and climate,” she said.

“It brings together expertise from all sectors—industry, academics, government and stakeholders—to focus on agriculture innovation with AI, particularly for the Southeast. The format of this conference was created to allow for knowledge sharing, as well as networking and greater exploration for future endeavors. Attending this event will provide the ‘spark’ for further innovation and collaboration among those with AI and agricultural interests across professions and across disciplines.”

Ortiz said in-person participation will allow networking, discussions for future collaboration and first-hand knowledge exchange. For those who cannot attend in person, a limited, virtual option will be available that will include access to plenary and breakout sessions.

More details and registration information are available on the conference website.

BY KRISTEN BOWMAN

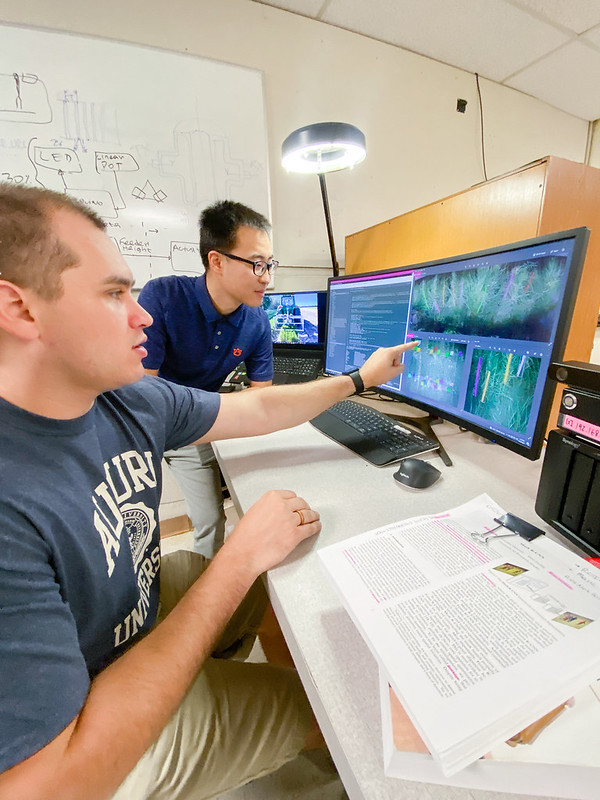

Auburn University will host the conference, “Envisioning 2050 in the Southeast: AI-driven Innovations in Agriculture,” March 9-11 at The Hotel at Auburn University and Dixon Conference Center. Pictured are doctoral student Rafael Bidese Puhl, left, and Assistant Professor of Biosystems Engineering Yin Bao.

Categories: Food Systems, Engineering, Agriculture

Auburn University-led study shows ancient cities also dealt with toxic pollution

The negative impact humans can have on their own environment is constantly on full display, with climate change, land alterations and harmful algal blooms impacting people’s lives daily.

But this isn’t an entirely new phenomenon, according to a recent study published in the “Proceedings of the National Academy of Sciences,” or PNAS, by Auburn University paleolimnologist Matthew Waters. PNAS is the official journal of the National Academy of Sciences and one of the world’s most cited and comprehensive multidisciplinary scientific journals.

The research leading to the study was a jointly funded project between the National Geographic Society and the National Science Foundation, which took Waters and his team to Lake Amatitlán in the highlands of Guatemala. The research also has been highlighted in the magazines “Popular Science” and “Scientific American.”

“Human-induced deforestation and soil erosion were environmental stressors for the ancient Maya of Mesoamerica,” said Waters, an associate professor of environmental science in the College of Agriculture’s Department of Crop, Soil and Environmental Sciences. “My study adds water quality/harmful algal blooms to the list of stressors, which was not addressed by the scientists previously studying the Maya.”

Waters also is a National Geographic Explorer and leads the Auburn PaleoEnvironmental Lab, where he and his team of researchers reconstruct historic data recorded in lake sediments and cave environments to document ecological change throughout time.

“Today, lakes worldwide that are surrounded by dense human settlement and intense riparian land use often develop algae/cyanobacteria blooms that can compromise water quality by depleting oxygen and producing toxins,” Waters said. “Such environmental impacts have rarely been explored in the context of an ancient Maya settlement.”

Blooms of algae and cyanobacteria can reduce oxygen in the water column and produce toxins. Such harmful algal blooms are typically caused by nutrient-dense runoff from human activities.

Waters and his colleagues from the University of Florida and the Universidad del Valle de Guatemala examined sediment from Lake Amatitlán in Guatemala to determine whether ancient Maya societies, which reached dense populations within the lake’s watershed, contributed to or were affected by algal blooms.

The study’s authors report that more than 1,000 years ago, harmful algal blooms rivaled eutrophic conditions currently found in the highland lake. The authors measured biomarkers for nutrients, algae, cyanobacteria and cyanotoxins in a sediment core representing approximately 2,100 years, from 110 BCE to present times.

The analyses revealed moderate nutrient and low cyanobacteria levels until 550 CE and a rise in cyanobacteria from 550 to 1200 CE, coinciding with the highest ancient population levels and human disturbance within the watershed.

Cyanobacteria declined in 1380 and remained low until around 1800, when current eutrophic conditions began. According to the authors, harmful algal blooms are not a modern phenomenon and should be considered among the factors that affected the ancient Maya population.

“Human-associated harmful algal blooms have affected both modern and ancient societies and deserve attention when exploring past human-environment interactions,” Waters said.

The study suggests that pre-Columbian Maya occupation of the Lake Amatitlán watershed negatively impacted water potability.

“Prehistoric cultural eutrophication indicates that human-driven nutrient enrichment of water bodies is not an exclusively modern phenomenon and may well have been a stressor for the ancient Maya,” Waters said.

BY PAUL HOLLIS

An Auburn University-led study examined sediment from Lake Amatitlán in Guatemala to determine whether ancient Maya societies, which reached dense populations within the lake’s watershed, contributed to or were affected by algal blooms. Pictured, from left, are Alehandra Agular, undergraduate student at the Universidad del Valle de Guatemala; Jason Curtis, senior associate professor of geology at the University of Florida; Mark Brenner, professor of geology at the University of Florida; Matthew Waters, associate professor of paleolimnology and environmental science at Auburn; and Ninoshka Lopez, undergraduate student at the Universidad del Valle de Guatemala.

Categories: Food Systems, Energy & the Environment, Agriculture

Auburn projects receive $1.6 million in latest round of state research development funding

Auburn University has been awarded $1.6 million in research grants from the state of Alabama through the Alabama Research Development and Enhancement Fund.

The grants, administered by the Alabama Department of Economic and Community Affairs, are earmarked for research and development of four different sustainability projects housed in the Samuel Ginn College of Engineering.

Of the $1,590,470 total awarded to Auburn:

-

$727,677 goes to research for producing jet and diesel fuels from woody biomass and waste plastics;

-

$294,008 goes to researching and assessing the economic feasibility of converting organic wastes into bioplastics;

-

$268,353 goes to conducting research involving polymer smart machines; and

-

$300,432 goes to developing soybean hulls as a means to keep aquaculture feed pellets in mass, resulting in less waste and more intake by farm-raised fish and shellfish.

The researchers include principal investigator Sushil Adhikari, professor and director of the Center for Bioenergy and Bioproducts, Department of Biosystems Engineering; principal investigator Peter He, associate professor, and co-principal investigators Jin Wang and Mario Eden, Department of Chemical Engineering; principal investigator Jason Clark, assistant professor, Department of Electrical and Computer Engineering; and principal investigator Zhihua Jiang, assistant professor and director of the Alabama Center for Paper and Bioresource Engineering Science, and co-principal investigator Burak Aksoy, Department of Chemical Engineering.

Summaries of the projects are as follows:

Title: Advanced Liquid Transportation Fuels from Co-Liquefaction of Forest Biomass and Waste Plastics

Investigator: Adhikari

The goal is to advance economic development in the state and nationally through reinvigoration of natural resource-based industries and to establish new industries based on advanced liquid fuels from woody biomass grown in the state and the waste plastics collected from cities. Woody biomass prevalent in Alabama will be co-liquefied with waste plastics using a pyrolysis technology, which will then be subjected to hydrogen treatment to produce jet and diesel fuels.

Title: A Novel Biotechnology That Converts Agricultural and Municipal Waste into Bioplastics

Investigators: He, Wang and Eden

Alabama is one of the top agricultural producing states in the U.S., with annual agricultural exports exceeding $1 billion. As a result, there is a significant amount of organic wastes produced in the state, and Alabama ranks 14th among all states in terms of biogas generation potential from organic waste through anaerobic digestion, or AD. These organic wastes represent an underutilized renewable feedstock for biofuel and biochemical production. This project aims at researching and assessing the economic feasibility of converting organic wastes into bioplastics. Specifically, the project will develop and optimize a prototype of a patent-pending biotechnology that enables the conversion of organic wastes into bioplastics, and to assess its technical and economic feasibility at scale through techno-economic analysis, or TEA.

In the proposed technology, a microalgae-methanotroph coculture will be cultivated in a novel patent-pending circulation coculture biofilm photobioreactor, or CCBP, to convert biogas (both methane and carbon dioxide) derived from organic wastes into microbial biomass while simultaneously recover chemicals from AD effluent to produce treated clean water. The produced mixed microbial biomass can be economically processed to produce high-value bioplastics that is in rising demand. The project will advance the progress of the patent pending biotechnology towards commercialization, which has potential to create many new jobs in the state of Alabama.

Title: Polymer Smart Machines

Investigator: Clark

This project aims to research and develop the foundational building blocks of “polymechatronics,” which will enable the realization of 3D printable polymer smart machines. The research includes designing, fabricating, modeling and characterizing piezopolymer versions of traditional active mechanical and electrical building blocks such as actuators, sensors, energy harvesters, energy storers and analog and digital circuit elements. Compared to traditional devices, polymer smart machines are expected to be less expensive, easier to manufacture, biocompatible, recyclable, use less energy, operate over a larger range of temperatures, offer new functionalities and be more environmentally friendly.

Title: A Novel and Sustainable Feed Binder from Soybean Hulls: Scale-Up Production and Evaluation

Investigators: Jiang and Aksoy

The goal is to establish a low-cost, high-value and novel compound feed binder from soybean hulls, a co-product of soybean processing for oil and meal production. The specific objectives of this project are: 1) to scale-up feed binder production to around 1.5 kg/hour and optimize process conditions for production; and 2) to scale-up shrimp feeding trials simulating shrimp farming operations at a commercial shrimp operation in west Alabama.

Successful completion of this project will establish a high-value and novel compound feed binder platform using 100% soy hulls that is ready for commercial scale productions and applications with significant economic and environmental benefits: It will significantly enhance competitive advantage of shrimp farmers in Alabama by reducing their feed costs. This will, in turn, improve employment opportunities in seafood farming and processing sector, making more local seafood and services available to the citizens of Alabama. In addition, it will also significantly improve water quality by reducing leached nutrients.

Auburn is among five Alabama universities and one research institution sharing in grants totaling $4.85 million, according to the announcement released recently by the Alabama governor’s office.

“Our universities and research institutions in Alabama truly impact the world, and I am proud to continue investing in the important work they are doing,” Gov. Kay Ivey said. “This $4.85 million is an investment in the future of Alabama and the future of research.”

BY MITCH EMMONS

Samford Hall

Categories: Food Systems, Energy & the Environment, Engineering, Auburn In the News, Agriculture

New Auburn University internal awards programs name winners for 2021

Auburn University launched two new pilot internal awards programs in 2021 and has named the program’s first recipients.

The Research Support Program, or RSP, and the Creative Work and Social Impact Scholarship Funding Program, or CWSI, were established by the Office of the Vice President for Research and Economic Development. Both programs provide a competitive internal funding source to support faculty and to provide an opportunity for them to experience a small-scale pilot and refine their projects before competing for larger awards.

“This is a pilot version of a larger intramural award program,” said Bob Holm, associate director of Proposal Services and Faculty Support, the unit that administers the programs. “It enables faculty to participate in a competitive funding program and make improvements to their projects before a commitment to a long-term award program is made. The pilot provides a platform to test what works and what does not.”

The RSP is intended to be an annual cycle funding program to foster the development and growth of innovative and transformational research activities. It builds on faculty expertise, stimulates interdisciplinary collaborations and strengthens seed research activities. It is a strategically focused Auburn investment that promotes promising and impactful new lines of research as well as the growth of collaborative and interdisciplinary teams to build the foundations of science, to overcome scientific and societal challenges and to promote and enhance the quality of life and wellbeing of individuals, groups and communities.

The CWSIS funding program fosters innovation and discovery and builds faculty reputation and competitiveness. Examples of prestigious recognition for CWSIS include: the McArthur Genius Award, the Gates Foundation Award, appointment to the National Council on the Humanities or the National Council on the Arts and an NSF Senior Advisor for Public Access. Disciplines associated with CWSIS include design and the arts, humanities and applicable areas within business, education, social sciences and health and well-being.

As a form of research, creative work poses questions and searches for the answers through iterative processes that demand intellectual rigor and hard work. Related scholarship narrates, analyzes and evaluates the production and products of creative work, or proposes new and innovative approaches to that work, including interdisciplinary collaborations and explorations. The goals of creative work and scholarship are ultimately tied to making significant contributions to a meaningful and dignified quality of life.

Social impact scholarship involves research that is specifically aimed at societal challenges and values both theoretical and applied domains to produce core knowledge and address persistent and complex issues to create a better world and improve the lives of all individuals. Research in this domain often engages a diversity of stakeholders with the goal of bringing beneficial effects and valuable changes to the economy, society, education, public policy, health and quality of life.

This year’s recipients are:

Research Support Program

Brian Albanese, College of Liberal Arts, $24,999.34; “Neurobehavioral sensitivity to negative reinforcement in suicide”;

Benjamin Bush, College of Architecture, Design and Construction, $24,987; “EX4C: Next Generation Blood and Vaccine Transport for Combat, Austere and Challenging Environments”; co-investigators: Lorenzo Cremaschi, Samuel Ginn College of Engineering; Joellen Sefton, College of Education; David Crumbley, School of Nursing;

Nathaniel Hardy, College of Agriculture, $25,000, “The Evolution of Virulence in Xylella fastidiosa”; co-investigator: Leonardo De La Fuente, College of Agriculture;

Amal Khalil Kaddoumi, Harrison School of Pharmacy, $25,000; “Amylin role in Alzheimer’s disease”; Co-Investigator: Ahmed Hamid, College of Sciences and Mathematics;

Peng Li, Samuel Ginn College of Engineering, $25,000, “Probing Novel Quantum Phases in van der Waals Magnet Fe5GeTe2”; co-investigators: Masoud Mahjouri-Samani, Samuel Ginn College of Engineering; Wencan Jin, College of Sciences and Mathematics;

Panagiotis Mistriotis, Samuel Ginn College of Engineering, $25,000; “Bioengineering tools to uncover the mechanisms of human mesenchymal stem cell migration”;

Kristina Neely, College of Education, $25,000; “Inhibitory Motor Control in Adults with ADHD,” co-investigator: William Murrah, College of Education;

Janna Willoughby, School of Forestry and Wildlife Sciences, $24,998; “How do environmental and genetic effects interact to determine individual fitness?”; co-investigators: Avril Harder, School of Forestry and Wildlife Sciences; Lana Narine, School of Forestry and Wildlife Sciences; Kelly Dunning, School of Forestry and Wildlife Sciences.

Creative Work and Social Impact Scholarship Funding Program

Junshan Liu, College of Architecture, Design and Construction, $20,000; “Digitally Preserving and Re-presenting Alabama’s Rosenwald Schools”; co-investigators: Gorham Bird, College of Architecture, Design and Construction; Richard Burt, College of Architecture, Design and Construction;

Alicia Powers, College of Human Sciences, $19,191.92; “A clinical-community pediatric wellness initiative to manage and prevent cardiometabolic diseases in children with limited resources in Alabama”; co-investigators: Jeanna Sewell, Harrison School of Pharmacy; Felicia Tuggle, College of Liberal Arts, Sarah Watts, School of Nursing.

More information about these and other funding support programs supported by the AU Office of the Vice President for Research and Economic Development can be found by clicking here.

BY MITCH EMMONS

Categories: Food Systems, Energy & the Environment, Health Sciences, Engineering, External Engagement, OVPRED, Creative Scholarship, Life Sciences, Agriculture

Biosystems faculty to train undergraduate researchers in bioprocessing with NSF award

Reduce, reuse, recycle. Especially if you can research cool, new ways to do it.

A team of Auburn faculty recently received a grant from the National Science Foundation to host a research experiences for undergraduates (REU) site, a program in which a university hosts 10 undergraduate students to do scientific research each summer. The project will focus on ways to convert waste into new and useful products through bioprocessing.

Led by Brendan Higgins, assistant professor of biosystems engineering and Sushil Adhikari, Alumni Professor of biosystems engineering and director of the Center for Bioenergy and Bioproducts, the 10-week program will be offered to a selection of students from a pool of undergraduate applicants studying at universities around the nation, who will each be paired to work directly with an Auburn University faculty member.

“The purpose of our site is to train them in research focused on converting waste materials and waste products back into products of value,” Higgins said. “So we have a team of faculty across the university who do research in this area, and we have four projects that the students will engage in.”

The program received $391,099 from NSF, with a focus on giving opportunities to underrepresented students. Students from around the country who go to universities that do not have research programs will have priority when it comes to this program, Higgins said.

“NSF’s goal when they created this program was to maximize the diversity of students that are able to experience research,” Higgins said. “We’re particularly targeting students who might not otherwise have the opportunity to do this.”

Students will do research either in a lab or in the field, depending on what kind of work is necessary for the individual project, Higgins said. Most of the 10-week period will be dedicated to research. A smaller amount of time, however, will be dedicated to professional development.

“The students are going to be learning how to become a researcher,” Higgins said. “Another theme of our site is teamwork. The communication aspect of science is also a big component.”

To do that, students will be encouraged to co-author a paper about their research with their faculty mentor, Higgins said.

“I kind of have this viewpoint that if you didn’t tell someone you did something, you didn’t do it,” Higgins said. “Also, publishing is really part of the scientific process. Telling people what you’ve discovered is really important.”

Some of the projects that the students will be working on include: making sensors for disease detection out of waste biomass, making adhesive out of discarded plant matter and upgrading agricultural waste water into protein. All of these projects will be significant in helping convert waste into useful products, which will help our planet long-term, Higgins said.

“The most impactful outcome we want from an REU site is a change in perception among the students,” Higgins said. “We want to know how the attitudes of our students changed throughout the program, and if they began to see themselves as a researcher during this program. Our hope is that this will reinforce and strengthen the desire in our students to continue their research career.”

The application for this REU site will open in September.

Media Contact: Cassie Montgomery, cmontgomery@auburn.edu, 334.844.3668

BY VIRGINIA SPEIRS

Sushil Adhikari and Brendan Higgins

Categories: Food Systems, Energy & the Environment, Engineering, Undergraduate Research, Agriculture

Auburn entomologist seeks alternatives for urban pesticide use

More than 80 percent of Americans live in expanding urban areas, and suburbanites are still craving greenspace as farmland gives way to housing developments and big-box stores.

The problem is that proud homeowners use significantly more insecticides than farmers, and these insecticides kill all insects, not just the pests. Insecticides also end up in creeks and rivers through runoff, leaching or accidental release, and exposure has been linked to human health problems.

David Held, chair of the College of Agriculture’s Department of Entomology and Plant Pathology, seeks to improve pest management in urban landscapes and turf grass systems (such as lawns, city parks, stadiums and golf courses) through a better understanding of ecological relationships in the systems. In particular, he has been studying Japanese beetles, one of the most economically important pests in North America, and now Europe, for 20 years.

This tiny, copper-and-green beetle packs an oversized punch as a threat to a wide range of plants, from rose bushes to birch trees.

The adult beetles attack foliage, consuming all the leaf material between the veins, leaving just a lacy skeleton. The immature stage, called a white grub, chews through grass roots, causing the turf to brown and die.

“This beetle can damage more than 300 species of plants, including row crops, fruits and ornamental horticultural crops,” Held noted. “And the grub, which consumes grass roots, accounts for most of the insecticide applied to suburban lawns.”

The Japanese beetle was introduced to the U.S. accidentally in the early 1900s. Before that, the pest was found only on the islands of Japan, isolated by water and kept in check by natural predators.

The grubs probably hitchhiked in the soil on imported iris roots. Without anything to check their growth, the beetle proliferated, becoming a major problem.

Held and his team are taking a multi-pronged approach to controlling this pest, as well as others. For one thing, they have evaluated the use of “plant growth-promoting rhizobacteria” (PGPR), which stimulate growth in the root system of a plant. These beneficial microbes colonize the soil around grass roots (the Greek root “rhiza” actually means “root”), forming a symbiotic relationship that encourages enhanced root growth, making the roots stronger and more capable of resisting pests.

Held’s team has confirmed that grass colonized by PGPR becomes more resistant to root-feeding insects, and two patent applications outline how PGPR can be used in conjunction with, or in place of, insecticides for integrated pest management of root-feeding pests.

He has also shown that PGPRs can be mixed with the insecticides currently used to manage root-feeding white grubs or mole crickets. In solution with insecticides, the bacteria can be sustained for at least two weeks.

Team members are Joe Kloepper, an emeritus professor in Entomology and Plant Pathology; John Beckmann from Entomology and Plant Pathology; and Adriana Avila Flores from the Department of Biological Sciences.

They are also experimenting with RNA interference (RNAi), which allows identification of a specific gene that is essential to the survival of a particular pest species and unique to that species. That specific gene is then targeted and “turned off.” Organisms without the targeted gene are not affected.

In particular, Held is experimenting with injecting the Japanese beetle with a small piece of double-stranded RNA (dsRNA), which is present in all cells and acts as a “messenger” that carries instructions from DNA to control synthesis of proteins such as enzymes.

Previous work by Held’s student showed that Japanese beetles rely on particular groups of enzymes to break down the protective toxins in plants, so their research is trying to target those enzymes. So far, they have attempted to target four genes; three in adults and larvae and one in larvae only.

“We have been successful in targeting one gene in larvae and are hoping to continue this research,” Held said. “We hope to eventually develop a commercial application, possibly a topical spray that would deliver the dsRNA like an insecticide.”

Held’s work has taken on added urgency because the Japanese beetle was discovered in Italy in 2014 and had spread to Switzerland by 2017. Europe does not allow the import of biological controls (which manage crop pests by using their natural enemies instead of pesticides), nor do EU countries have the insecticide options available in the U.S.

Targeted control with RNAi would limit the negative effects of insecticide applications and could be used in Europe as well as the U.S. Another possibility is to engineer the PGPR bacteria, which are already able to enter turfgrass with ease, to produce novel dsRNA while living temporarily inside plants. This would enable a plant able to temporarily defend itself against Japanese beetles without the use of chemical insecticides.

Insecticides are necessary to prevent damage from insects to lawns and landscape plants, but chemical insecticides are rarely selective and kill beneficial insects along with pests; in fact, insecticides are one cause of the precipitous decline in honeybees.

“Development of alternative methods of pest control that are able to target specific pests, without affecting other insects, wildlife or humans, is essential,” Held said. “And we absolutely must develop new, reduced-risk technologies to lessen our dependence on chemical insecticides.”

BY JACQUELINE KOCHAK

David Held

Categories: Food Systems, Energy & the Environment, Agriculture

Auburn University researcher developing management practices for problem algal blooms in aquaculture

Aquaculture is the fastest-growing sector of animal agriculture; however, sustainable expansion and intensification of aquaculture is severely hampered by issues related to aquatic animal health.

A researcher in Auburn University’s School of Fisheries, Aquaculture and Aquatic Sciences is focused on developing programs to help the aquaculture industry better manage problematic algae growth in ponds and other water sources.

Alan Wilson, professor and assistant director for instruction in his school, is partnering with the Aquatic Animal Research Unit of the U.S. Department of Agriculture-Agricultural Research Service, or USDA-ARS, to conduct research involving catfish growers in west Alabama.

“We are currently focused on projects involving 21 ponds across five catfish farms,” Wilson said. “We are monitoring algal growth and gathering environmental data to help those growers establish best management practices for water quality.”

Wilson says algal blooms can be a normal occurrence in ponds with elevated nutrients, but there is an urgent need to manage water quality in aquaculture ponds that favors beneficial algal communities versus those that can be harmful to the fish.

“A ‘green pond’ can be a good thing in the healthy context,” Wilson said. “Algae are important, as they produce oxygen. But blooms can also become too abundant with harmful types of algae, creating conditions that kill the fish. This is what our control focus is on.

“We are developing new detection, prevention and control measures for harmful algae to reduce fish/shellfish mortality, safeguard animal performance and ensure product quality.”

Harmful algal blooms are occurring with increased regularity and severity in freshwater, estuarine and marine systems around the world, according to Wilson. These harmful algal blooms have brought about large-scale catastrophic losses of valuable catfish and shrimp, particularly in the summer months immediately prior to harvest.

In Alabama alone, since 2015, mortality levels attributed to harmful algal blooms have surged to nearly 1 million pounds of catfish annually, according to Wilson’s USDA-ARS collaborator Benjamin Beck.