Industrial and systems engineering assistant professor earns NSF CAREER Award for AM fatigue life prediction through deep learning

Four years ago, GE Aerospace transitioned to using additive manufacturing (AM) for their new Catalyst turboprop engine. Which meant that 800 traditionally manufactured components were consolidated into just 12 metal AM parts, the development cycle was dropped from 5-10 years to only two, the engine weight reduced by 5% and the fuel consumption improved by 1%. For G.E., that's a pretty big deal. If other U.S. aircraft manufacturers went the same route, that would be a pretty big deal for the planet.

There's a reason AM research across the globe is expected to push $24 billion by 2027, and the revolutionary impact on the aviation industry is one of them. Experts estimate that substantial adoption of 3D-printed parts could knock 200 million gallons off of annual aviation fuel consumption.

If the parts work.

Despite the demonstrated success of metal additive manufacturing in various industries, the performance uncertainty of AM parts undermines the potential of deploying AM for high-consequence applications. Air travel. Space travel. Those sorts of thing.

Which is why the National Science Foundation (NSF) is turning to assistant industrial and systems engineering professor Peter Liu in the form of a $500,000 CAREER Award meant to generate new insight into defect formation relevant to fatigue performance of parts manufactured through laser powder-bed fusion (LPBF) and uncover the synergistic impacts of multi-scale factors on fatigue fractures.

Liu hopes the five-year project, Deep Learning to Understand Fatigue Performance and Processing Relationship of Complex Parts by Additive Manufacturing for High-consequence Applications, "will establish a physics-centric, machine learning framework for fatigue life predictions, serving as a technological foundation for future metal AM production of dynamic load-bearing applications and establishment of a resilient and reconfigurable supply chain, and thus, enhance the competitiveness of U.S. industry.”

"The biggest challenges in fatigue performance assessment for LPBF parts come from the nonhomogeneous microstructural traits from process dynamics, coupled with their complex geometry and imposed multiaxial loading," he said. "Current fatigue performance assessment methods and tests are unable to take all these contributing factors into account."

Liu believes the best way to address those challenges is to combine fracture mechanics, finite element (FE) methods and novel data-driven models.

"The goal of this early career effort is to understand fatigue failures of complex LPBF parts under multiaxial loading for data-driven fatigue life predictions," he said. "The research will investigate the nature of fatigue failures from plastic deformation and crack initiation at the highest stress concentrations and translate fatigue life predictions into evaluating the crack growth at the vulnerable zones using a multiscale approach. Then we will develop new statistical models and a novel multiscale multifactorial deep learning model to incorporate crack growth and stress distribution to understand their impacts on fatigue performance and predict fatigue life."

Liu is also the principal investigator on another recent NSF project aimed at applying deep learning to AM development.

"My research passion is synergizing machine learning and fundamental process physics to advance manufacturing knowledge, efficiency, and capability of LPBF," Liu said. "I am extremely grateful to the support from my department, the college, the National Center for Additive Manufacturing Excellence (NCAME), the Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) and the AI@AU Initiative. This CAREER project aligns with one of the strategic areas of research in advanced manufacturing and materials at the Samuel Ginn College of Engineering. It will contribute to the leading research and education capabilities in advanced manufacturing at Auburn, accelerate AI applications in manufacturing, and increase interdisciplinary collaboration at Auburn."

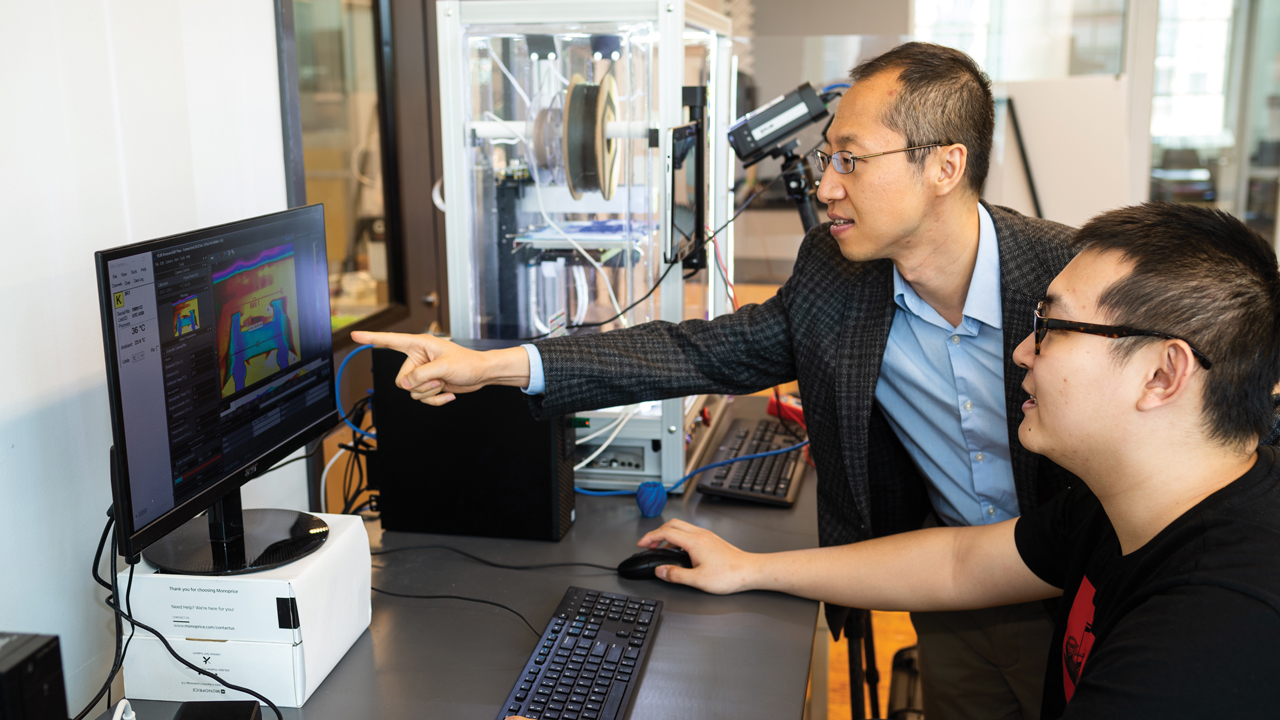

Peter Liu, left, recently received an NSF CAREER award to support his research into deep learning's application in predicting fatigue performance in additive manufacturing.

Categories: Transportation, Engineering, Manufacturing, Advanced Systems

Back to Articles