The mission of Auburn University to improve the lives of the people of Alabama, the nation, and the world through forward-thinking education, life-enhancing research and scholarship, and selfless service, extends beyond the physical campus itself. Auburn University has off-campus instructional sites located at various locations and in order to keep these locations safe, instruction-focused, and forward-thinking, Risk Management and Safety conducts off-campus site assessments to mitigate and identify risks and issues. The process is outlined below.

Any off-campus instructional facility/program defined as having 50% or more of instruction provided is included in the Off-Campus Instructional Site Assessment Process.

A list of sites will be obtained by the Safety and Health Specialist serving as Site Assessment Coordinator. Site visits will be initially prioritized based on an understanding of risks associated with known activities performed at that site.

Once the sites have been identified, the Site Assessment Coordinator will initiate the Off-Campus Instructional Site Assessment Process.

As sites are identified, the Site Assessment Coordinator will identify a site point of contact to aid in collecting data needed for this process.

To ensure that all facilities and operations are evaluated thoroughly, the below items include, but are not limited to, site-specific information that will be obtained for each facility before the site visit:

- Address of all facilities

- Ownership of each property (leased or AU owned)

- Building construction components

- Occupancy classifications

- Square footage

- Property Maintenance

- Fire and Life Safety Equipment Management

- List of any equipment used for instruction (tractor, hand tools, band saw, etc.)

This information may be obtained before the site visit, verified upon physical assessment and evaluation, and maintained by the Site Assessment Coordinator.

This information will aid in correct facility identification and determine Risk Management and Safety (RMS) resources for site visits.

Hazard data will be collected on activities performed by students, faculty, and staff and the facilities in which these activities occur.

Job Activities are broken down into the following categories:

- Animal Care

- Biological Exposures

- Chemical Use and Exposures

- Fire Arts Operations

- General Safety Operations

- Radiological Equipment and Exposures

- Regulated Activities (ex. Pesticides, Regulated Waste, Hazardous Building Materials)

- Respiratory Hazards

- Machinery Equipment and Use

- Vehicle Usage

Once RMS Program involvement has been identified, each program will select at least one program representative to participate in the physical evaluation and assessment of the site. This includes data collection initiatives, physical site visits, and follow-up visits as needed.

The Site Assessment Coordinator or other selected RMS representative will be selected as the team leader to coordinate and organize data collection, site visit schedule, and follow-up items.

Based on information collected from the job activities and associated hazard data collection, the selected RMS representatives will begin to collect available data including:

- Previous RMS site visit documentation

- Previously identified procedures, programs, and policies associated with the site and site activities.

- Training records

- On-the-job, near misses, and incident records and investigations

If data is not available, the RMS representative will communicate this to the Project Coordinator who will collaborate with the site contact to collect and distribute any available documents to RMS working group.

When all relevant information has been collected, the Site Assessment Coordinator will work with the site contact to schedule a site visit. The length of time appointed to conduct the site visit is determined by the scale of the activities that are being performed. Along with the RMS representatives, members of the instructional site’s leadership and operations team are to be present and/or available to answer questions.

The site visit will include a physical evaluation of the following:

- All facilities associated with the instructional programs.

- This includes leased spaces.

- All equipment used by students, faculty, staff, and employees (ex. Machinery, vehicles, powered industrial equipment, etc.).

- If applicable, living quarters that are managed by Auburn University.

During the site visit, each RMS representative will be reviewing procedures relevant to their program area and professional expertise. Any item identified as a concern that is outside the scope of RMS's responsibility will be forwarded to the appropriate department as part of the final report.

Any item identified that is of an immediate threat to life or health will be addressed before RMS leaves the site. Corrective actions may include an immediate suspension of activities.

Each identified hazard that requires corrective action will utilize the hierarchy of controls to lower and or eliminate hazard exposure and reduce the risk of illness or injury. The hierarchy of controls is used to determine which actions will best control exposures. There are five levels of action which are listed below in the preferred order of action based on effectiveness:

- Elimination

- Substitution

- Engineering Controls

- Administration Controls

- Personal Protective Equipment

ELIMINATION

Elimination removes the hazard at the source. This is the preferred solution to protect workers because no exposure can occur.

SUBSTITUTION

Substitution is the use of a safer alternative to the source of the hazard. Any substitution must be assessed to ensure its effectiveness and for any potential harmful effects. It must not create new risks.

ENGINEERING CONTROLS

Engineering controls reduce or prevent contact with the hazard. This includes equipment modification, protective barriers, ventilation, etc.

ADMINISTRATIVE CONTROLS

Administrative controls establish work practices that reduce the duration, frequency, or intensity of exposure to a hazard(s). This includes process training, activity rotation, breaks, adjusting speeds, etc.

PERSONAL PROTECTIVE EQUIPMENT

Personal Protective Equipment (PPE) is equipment worn to minimize exposure to hazards. Examples include gloves, safety glasses, hearing protection, hard hats, and respirators. The recommendation of PPE is only used when the other control methods are unable to reduce the hazardous exposure to safe levels.

Upon completion of the site visit by the designated RMS programs, the RMS Site Assessment Coordinator will facilitate the collection of data obtained during the visit and organize it into the Off-Campus Instructional Site Assessment Report.

The report will include the following:

- Location of the observed hazard.

- Safety and health concerns specific to hazard.

- Existing controls present to mitigate hazard exposure.

- Corrective actions needed to effectively mitigate hazards including regulatory-specific requirements regarding concern.

- Personnel responsible for corrective action completions.

- Risk Rating

- Follow-up Requirements

The RMS working group will complete the report and send it to the site contact within two weeks of the site visit.

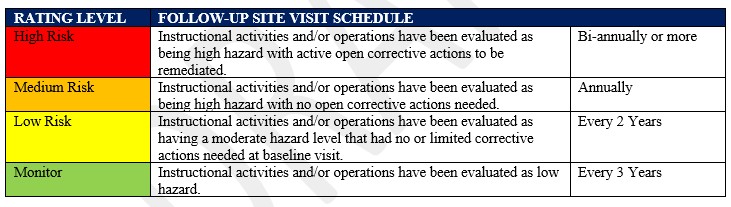

Each site will be placed on a routine follow-up schedule based on the hazard rating given following the initial visit.

The follow-up schedule will be determined as follows:

The frequency of site visits is subject to change. Factors that determine a visit outside the initial follow-up site visit are as follows:

- Significant On-the-job injury, near miss, or incident occurring at the site.

- Increase in On-the-job injuries, near misses, or incidents.

- Changes in activities occurring on site that are deemed hazardous.

- Reported safety concerns

The RMS Site Assessment Coordinator will manage the site visit schedules and update them with any changes.

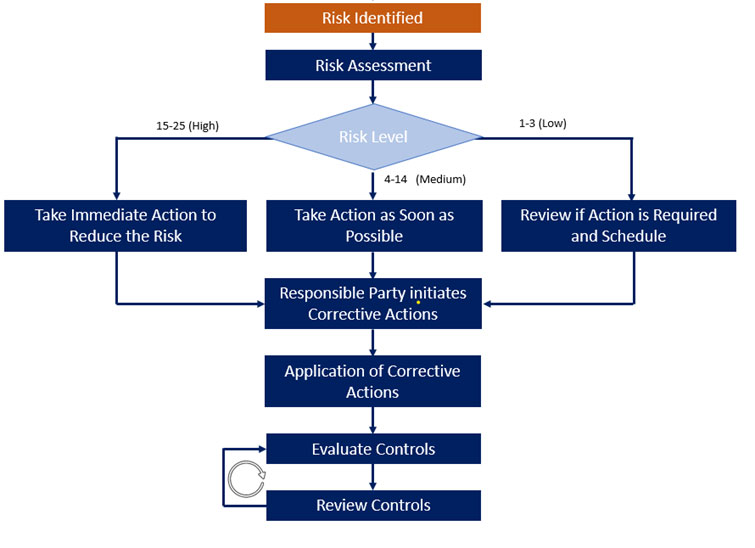

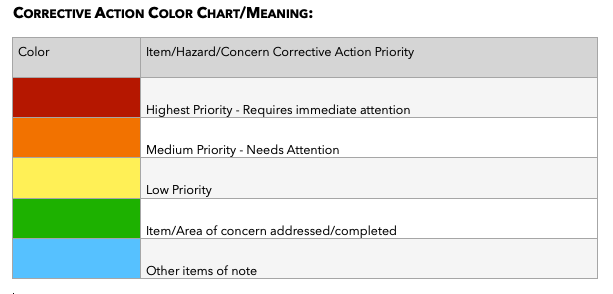

All assessments, hazards, and/or incidents, will be evaluated based on the risk identification process illustrated below.

Upon completion of the site visit, the Site Assessment Coordinator will begin working with RMS representatives to organize evaluation data, assess hazard ratings, and recommend corrective actions.

The ratings identified for each item will be used to identify the priority at which corrective actions are to occur.

These corrective action ratings will also aid in determining the site visit follow-up schedule.

Upcoming Events

| View All Events |